- Home

- Forums

- Ride Reports

- MotoBikes

- Restorations

- Wrenching

- 1963 BMW R69s

- 1969 BMW R60/2

- 1978 Yamaha 125

- 1979 KZ1300

- 1979 Kz1300 - Bob's Beauty

- 1981 CBX SuperSport

- 1981 Kz1300 Model A3 - Chocolatie

- 1984 Ford F250 XL

- 1987 ATK

- 1987 MowieMowie

- 1987 RotoTiller

- 1988 Honda Accord Lxi

- 1990 BMW RT100 - Barrie

- 1991 Harley Davidson FLHTCU

- 1992 Johnnie Deere

- 2000 YZ426

- 2002 Dodge Ram

- 2006 Carson RacerX Trailer

- 2006 Host Camper

- 2006 KrZy8

- 2007 Wabs

- 2012 KTM 690R

- 2013 Naomi - FJR 1300

- 2014-08-01 Air Compressor - Sears

- 2017 Kioti

- 2018 Toy Hauler

- 2020 Honda Fit

- 2021 Miscellaneous

- 2024 Log Splitter

- 2024 NeoDyne MC Lift

- 2050 test

- Lil Trlr

- Eats

- RIP

- PC Not

- Cages

- Test

- FJRF Best

- For Sale

Candy Butt Association

World's Wimpiest Riders

You are here

2024-09-20 AC-004 Assembly

Forums:

I paid extra to have the it 'assembled'. Didn't know 'ASSembly' did NOT include the extra crap needed for a high elevation tail gate.

...and I hate assembly. Suck at jig saw puzzles. Tab A into Slot B = Screw C..

Seriously. Minimal spatial capabilites of space A into vacuum B. We can't all be good at everything..

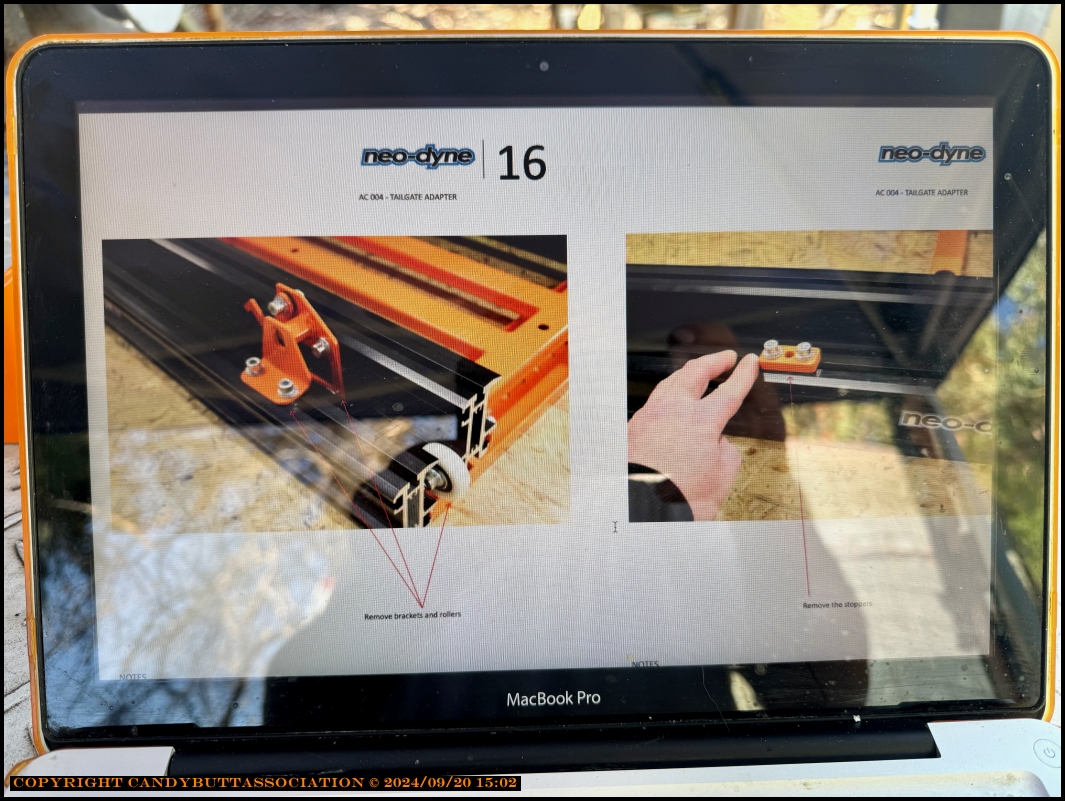

Laptop and iPhone with low res instructions.

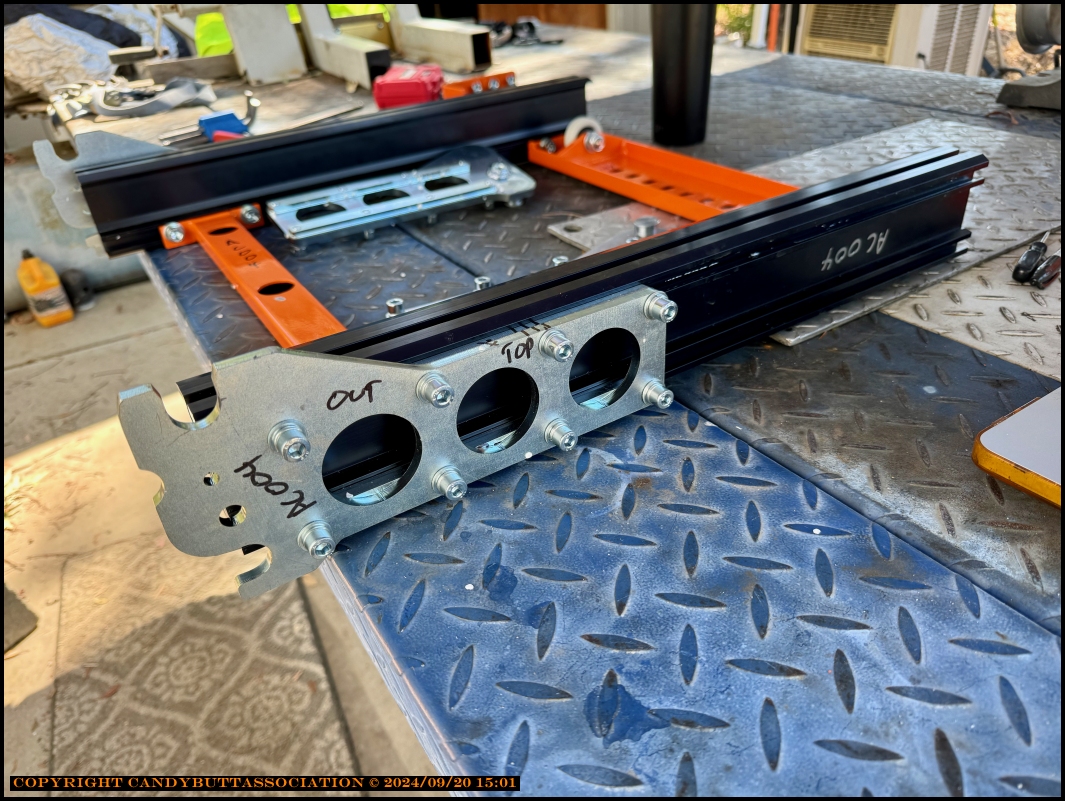

Marked the crap outta EVERYTHING. Hey, if you you know you suck at a job.. take extra precautions?

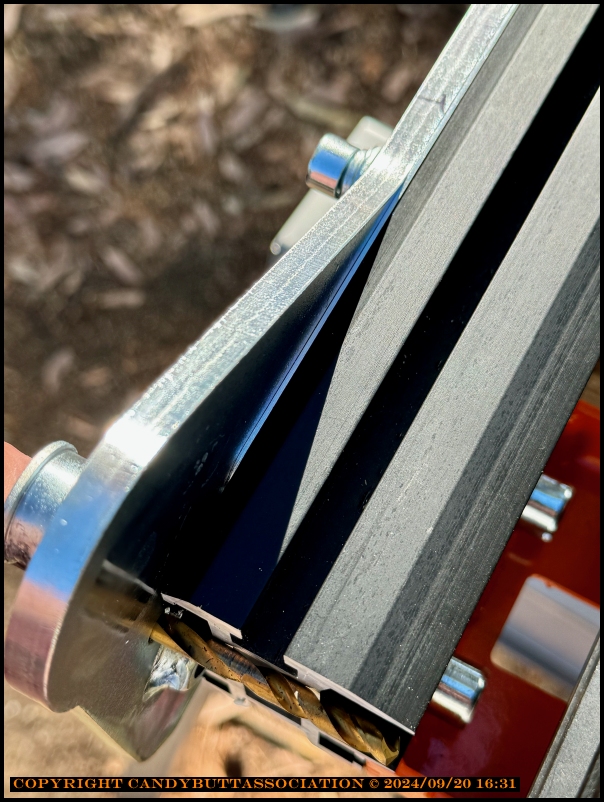

Assembling the tailgate extender.. This ramp has the outer part that straps or bolts to the bed,

the inner track that moves up and down. Really, how hard could it be?

EVERYTHING, excep this one part, fit perfectly. Obviously stamp cut, and it left and edge.

Had to break out Dad's grinder to make it fit. Fortunately, I grind mower blades, I am an exPert!

Finally.. it fits.

It's funny. Not. When thinking in my own head, it all works. When trying to assemble another persons idea..

Tab A to Slot B, with inner and outer and upside down too..

This is the external piece.. straps/bolts to truck bed. This is the 'tailgate extender'...

Instructions were OK, but newer design pieces looked different. Another challenge.

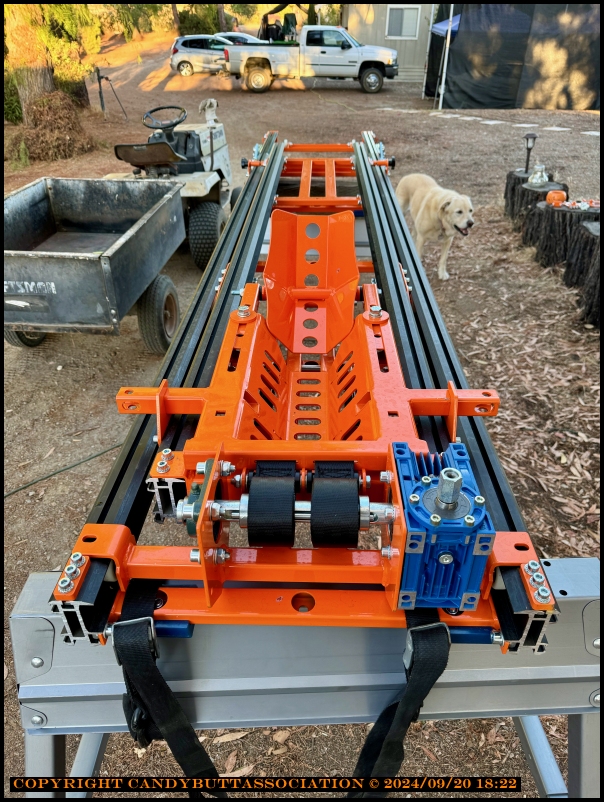

Bought some saw horses and used the tractor to get the assembly off the ground. Hydraulics are your friend! 330 pounds.

Full extension minus the tail gate adapter.

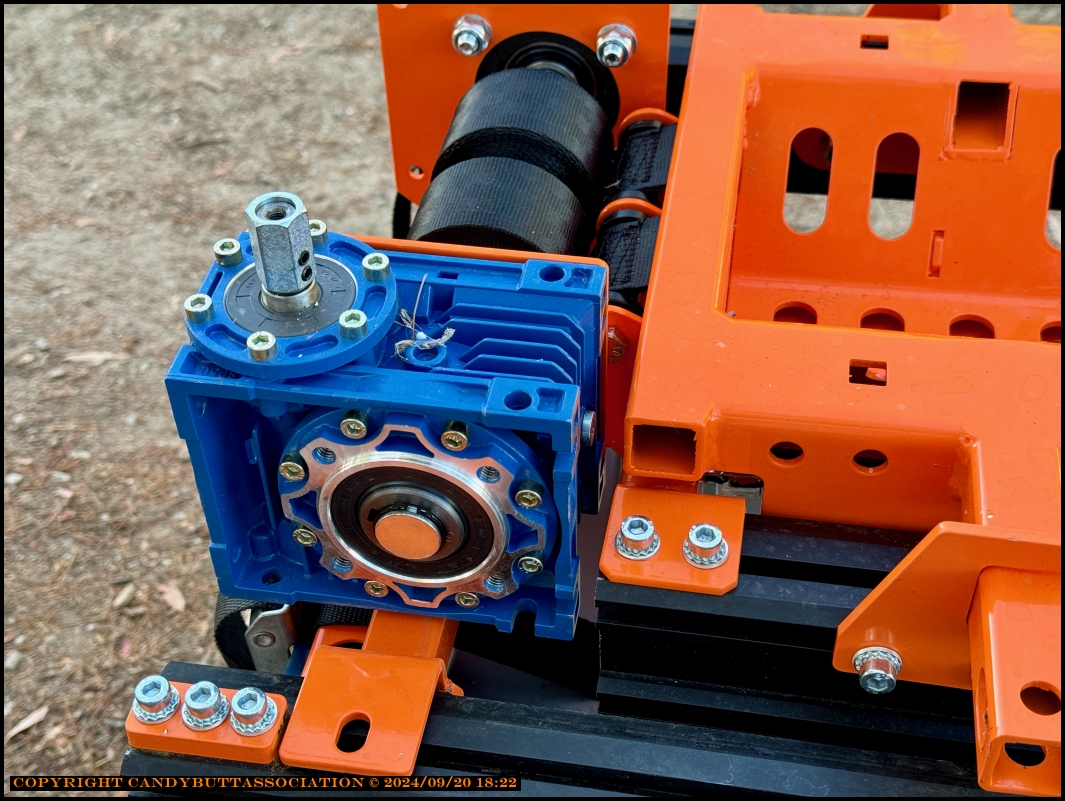

Oil filled worm drive is the mechanical advantage. Straps used to pull..

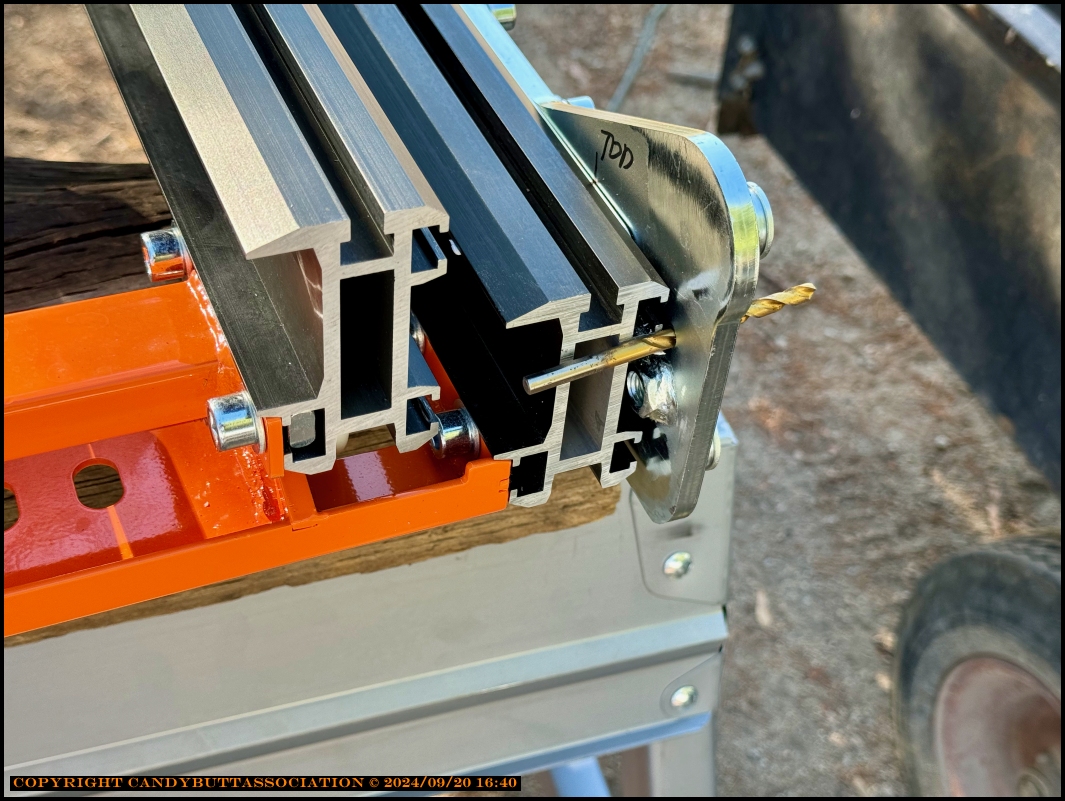

Pretty obvious this is rev 2. The slender spacer between the outer bracket and aluminum frame indicates so..

Instructions said to use a 6mm bit to ensure correct quick disconnect / hinge spacing. Was close, but had to adjust later.

Instructrions said 1mm gap was good. Got it. At the hinge point.

Clever engineering.. extruded rails, captive nuts, quality hardware. Of course, for 5k it better be!

When one has little spatial conceputality, copious notes are good!

With that, I'm done. Ride tomorrow, assemble inner, slide rail later?

Theme by Danetsoft and Danang Probo Sayekti inspired by Maksimer

2024-09-18 NeoDyne - More Pics, Forgotten Pics, and Ooopsies

Got out of order with posting.. Oh well. It happens.

Delivery truck too big for dirt road, picked up at hiway..

x

Neighbor has tractor with forks.. over 300 pounds worth of parts..

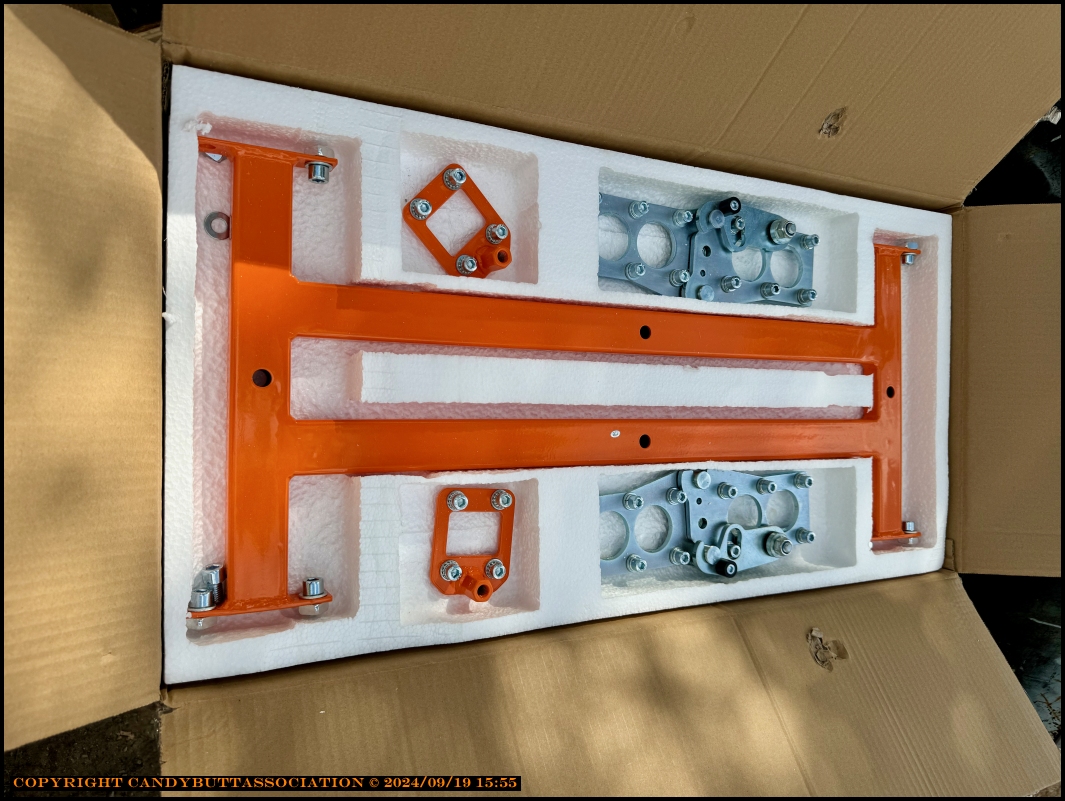

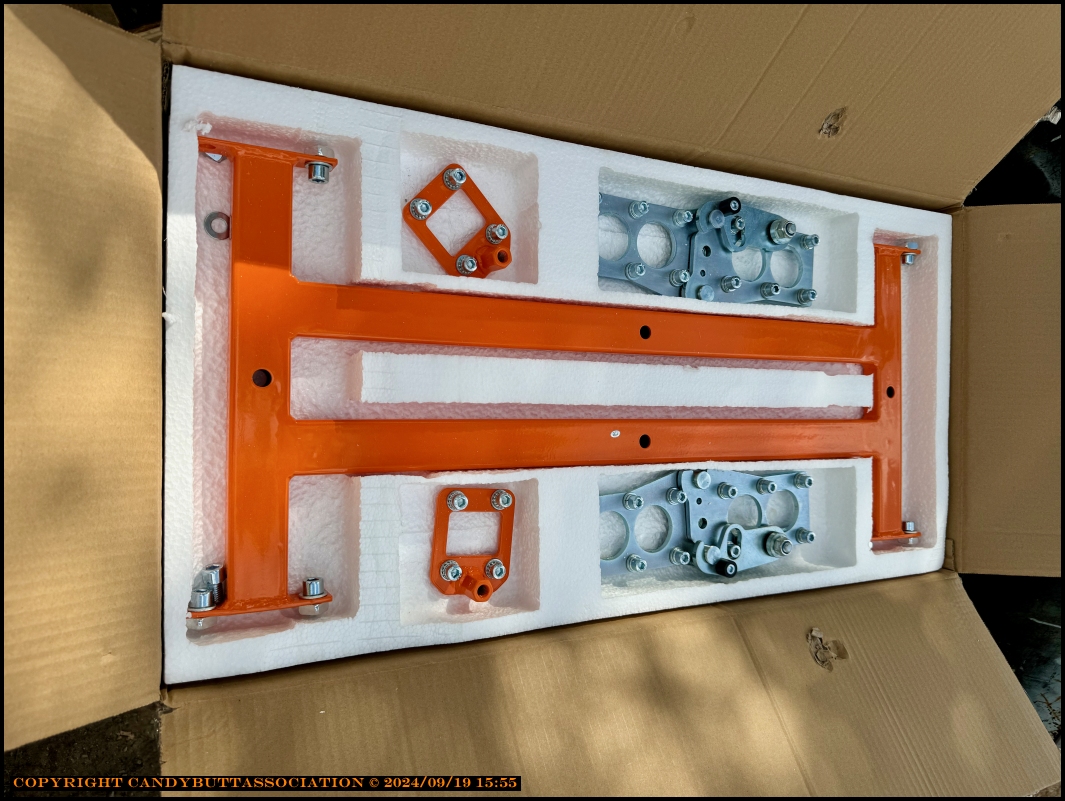

Time to unpack!

Tie-Down kit.

Well packaged..

x

x

No instructions in kit?

x

Heavy duty quick-disconnect hinges..

x

The main guts..

x

Hydraulics are your lifting friend!

The fun begins.

x

The only part that didn't fit. Had to grind it down..

Remove material here, Don!

Better.

x

x

x

Some instructions were good, some ok, some just sucked...

x

x

x

Getting correct hinge alignment was tough. The 'use a drill bit' to properly align failed miserably.

x

x

x

x

x

x

x

Simply could not figure out what would stop the trolley from over-extending.

x

The instructions didn't say 'why' the components had to be in certain locations.. Just blindly put it here.

Turns out the 'stop' is bracket AC-004.. It contact the inner rail roller wheels.

x

Trouble with alignment starts. It was off enough that the trolley would hang up, not slide down without encouragement.

How to fix it comes later.

x

x

x

x

Test run with light bike.

x

x

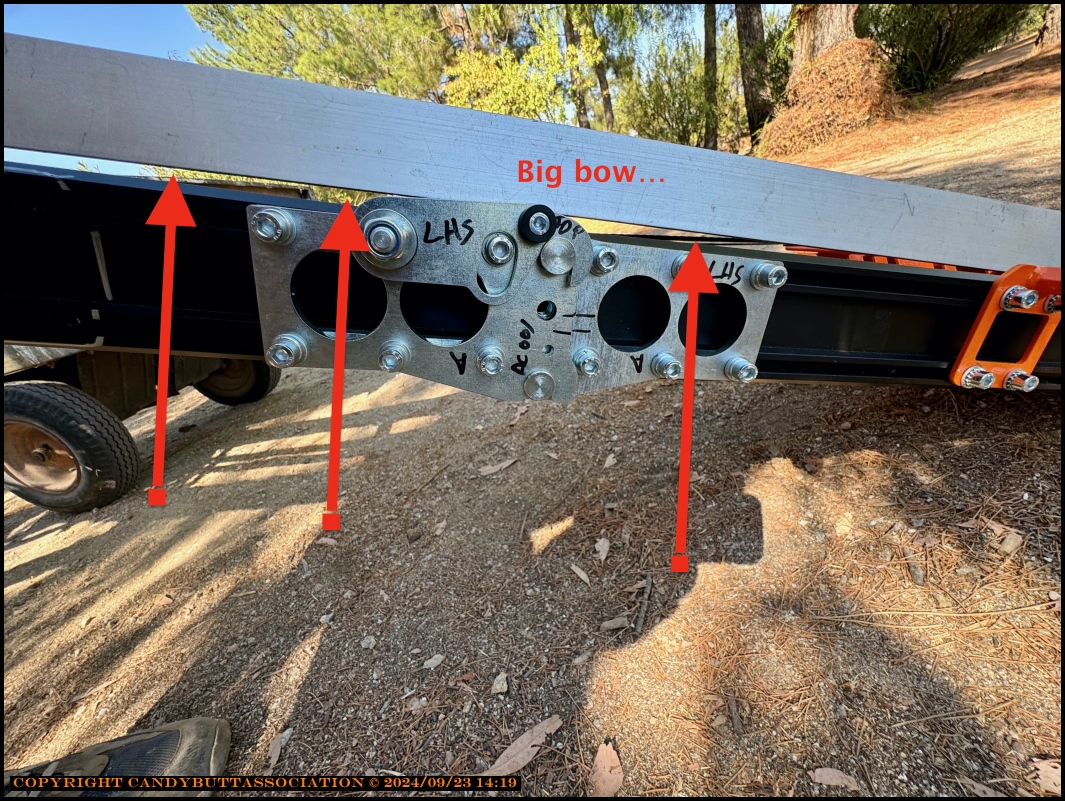

As far as I could go, the ramp front end was lifting up, even though I had two big concrete piers attached.

And this bow developed.. Not good.

x

x

x

So I quit and went pricing drill motors at Miners..

x

x

Sandy and Morris called from EZ Cycle Ramp to discuss and remedy the issues.

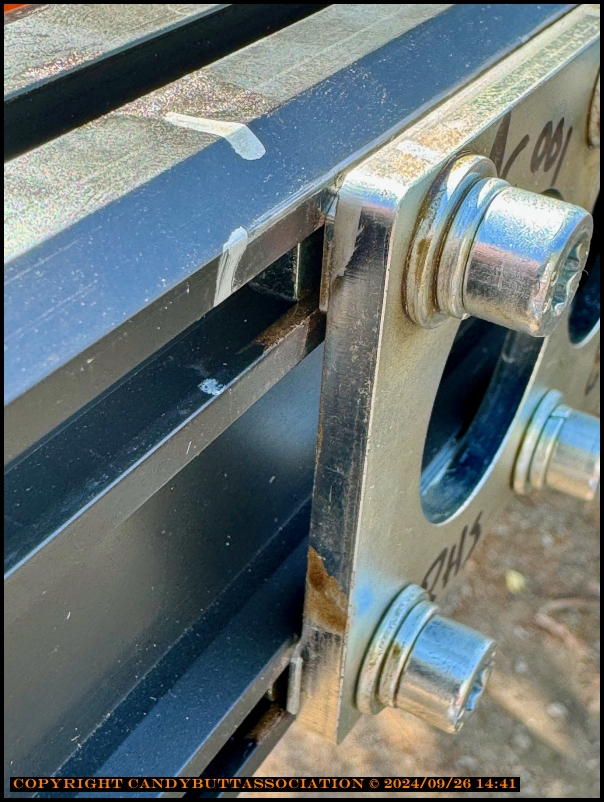

After carefully looking it over, and deciphering the so-called instructions,

found that the 1mm wide spacer goes between the rail and hinge, and NOT

INSIDE the rail.

Also re-purposed this as a second mechanical stop for the inner slide rail.

Right when I thought all was good, noticed the mis-alignment of the rails.