- Home

- Forums

- Ride Reports

- MotoBikes

- Restorations

- Wrenching

- 1963 BMW R69s

- 1969 BMW R60/2

- 1978 Yamaha 125

- 1979 KZ1300

- 1979 Kz1300 - Bob's Beauty

- 1981 CBX SuperSport

- 1981 Kz1300 Model A3 - Chocolatie

- 1984 Ford F250 XL

- 1987 ATK

- 1987 MowieMowie

- 1987 RotoTiller

- 1988 Honda Accord Lxi

- 1990 BMW RT100 - Barrie

- 1991 Harley Davidson FLHTCU

- 1992 Johnnie Deere

- 2000 YZ426

- 2002 Dodge Ram

- 2006 Carson RacerX Trailer

- 2006 Host Camper

- 2006 KrZy8

- 2007 Wabs

- 2012 KTM 690R

- 2013 Naomi - FJR 1300

- 2014-08-01 Air Compressor - Sears

- 2017 Kioti

- 2018 Toy Hauler

- 2020 Honda Fit

- 2021 Miscellaneous

- 2024 Log Splitter

- 2024 NeoDyne MC Lift

- 2050 test

- Lil Trlr

- Eats

- RIP

- PC Not

- Cages

- Test

- FJRF Best

- For Sale

Candy Butt Association

World's Wimpiest Riders

You are here

2025-01-16 KZ1300 Carb Diaphragms, Bowl Screws

Forums:

2025-01-16

New Diaphragms and Float Bowl Screws - 1979 KZ1300

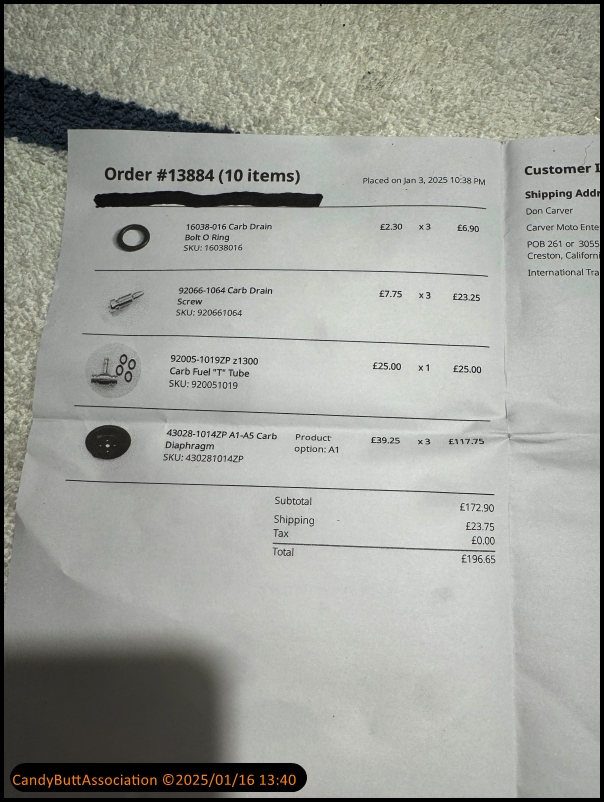

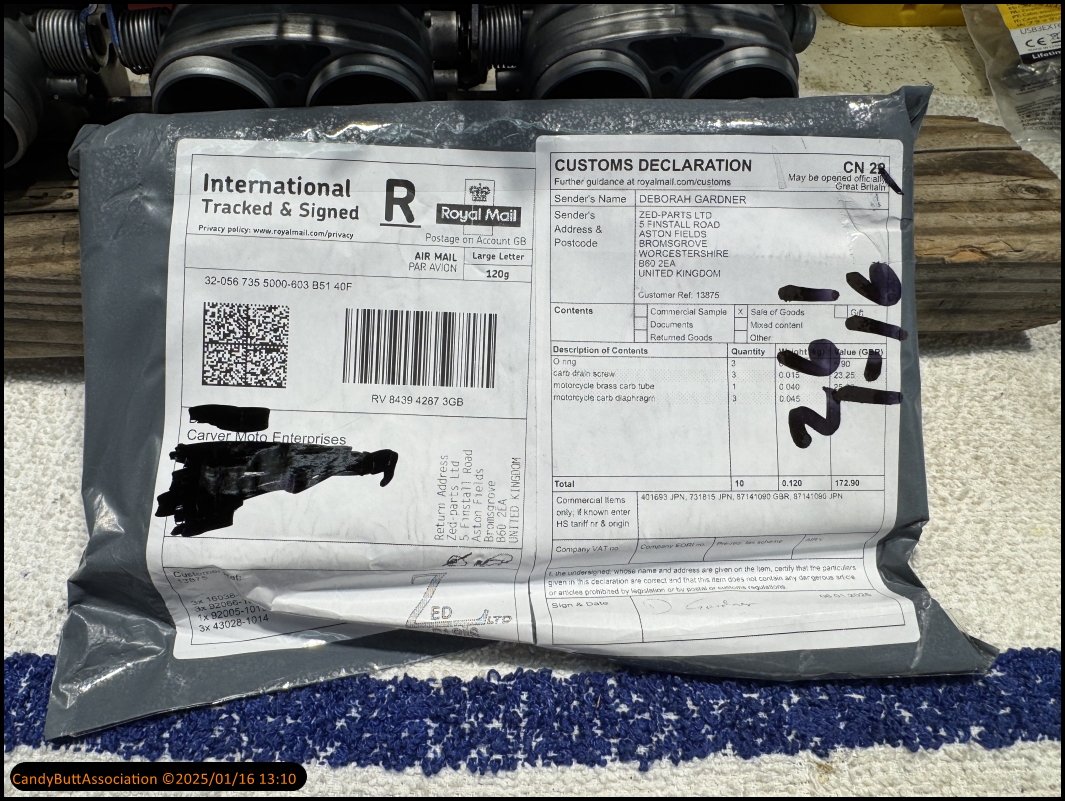

Bought some carb parts from Zed-Parts, jolly old England.

A new fuel manifold brass T, three new drain screws, three new O-rings for the float bowl, and three new diaphragms.

They are very supple, flexible. They appear to be the same thickness as the original manufacturer.

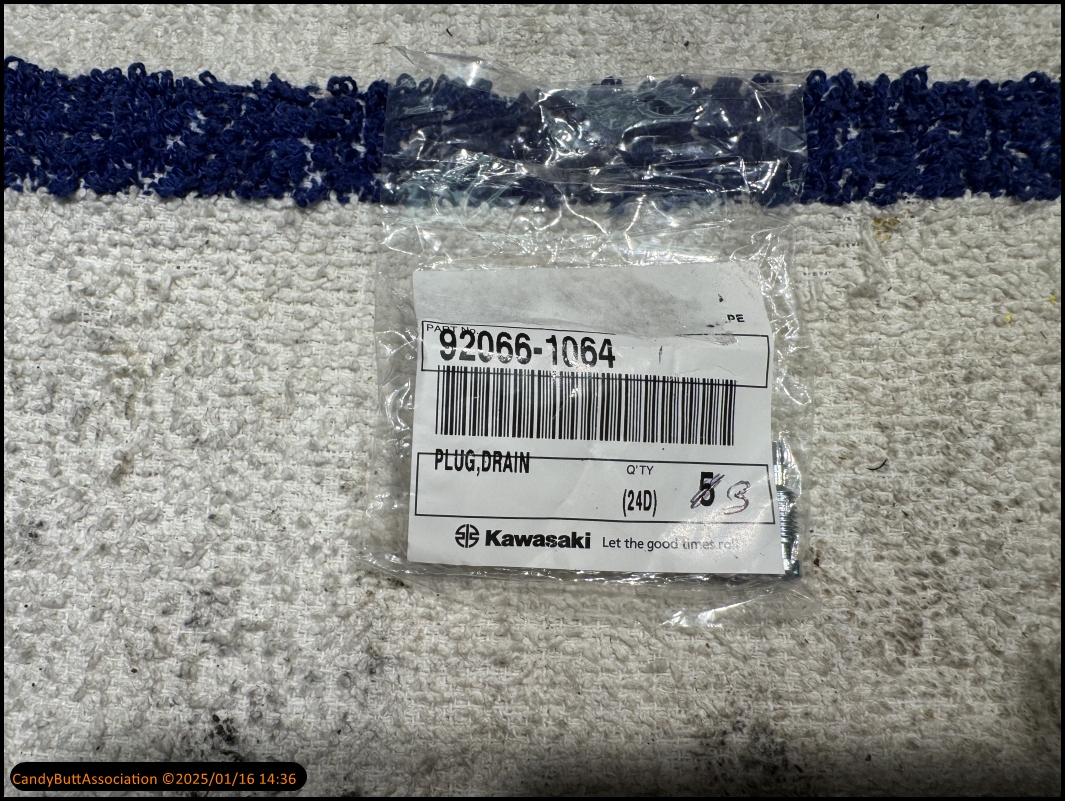

These appeared to be genuine Kawasaki parts.

I bought this carburetor rack from eBay, the float drain screws were pretty buggered up.

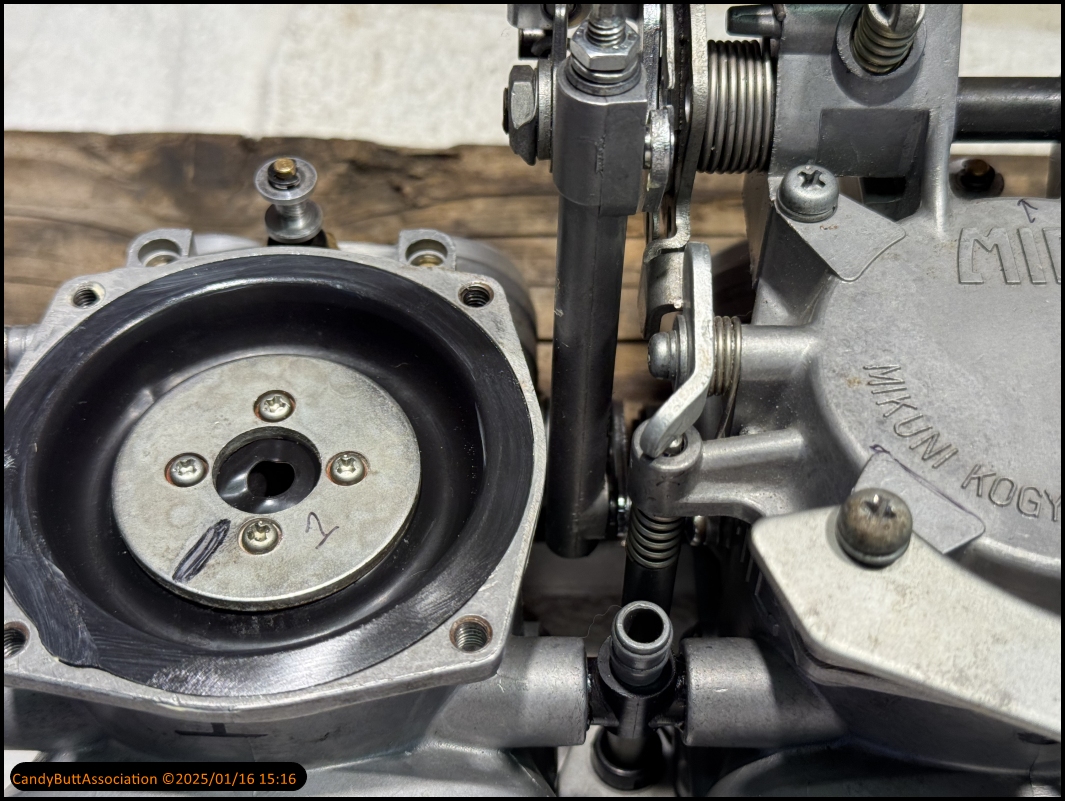

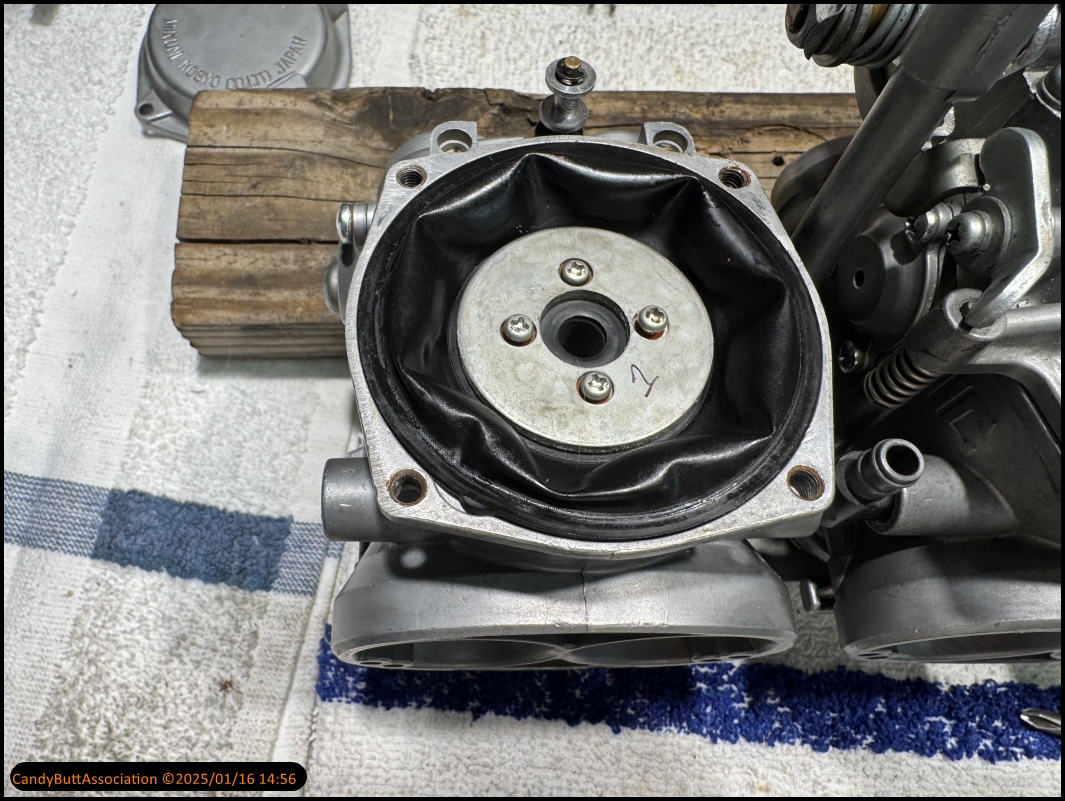

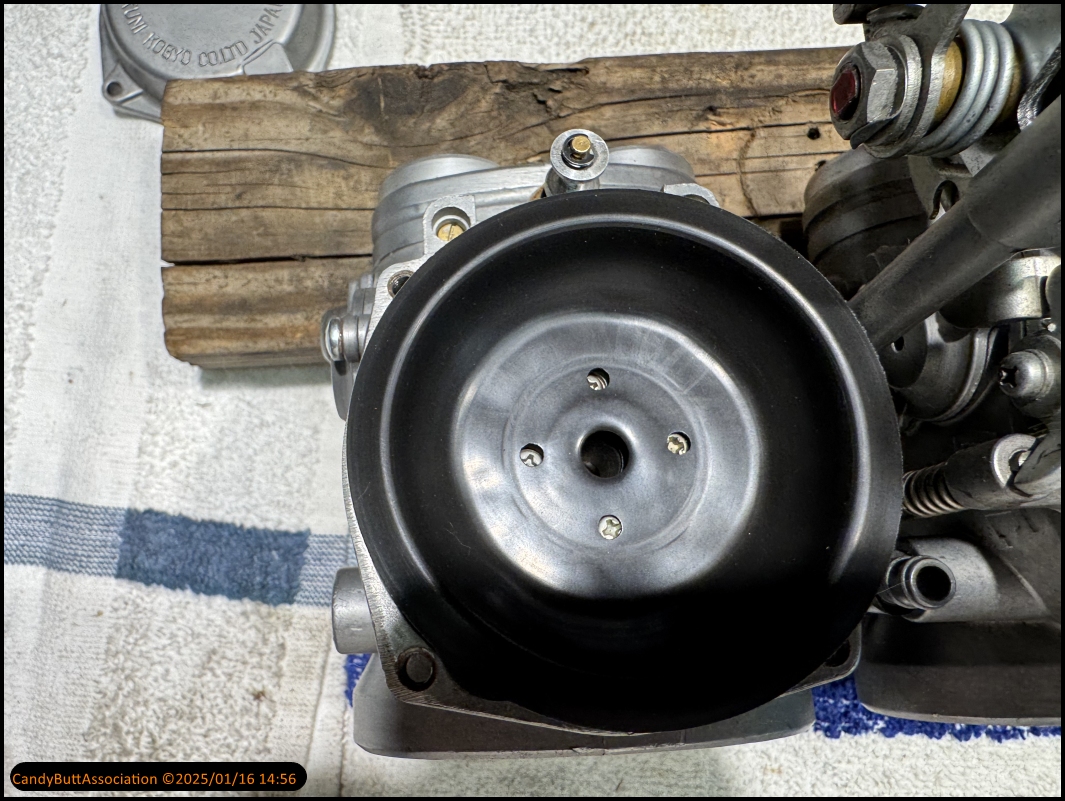

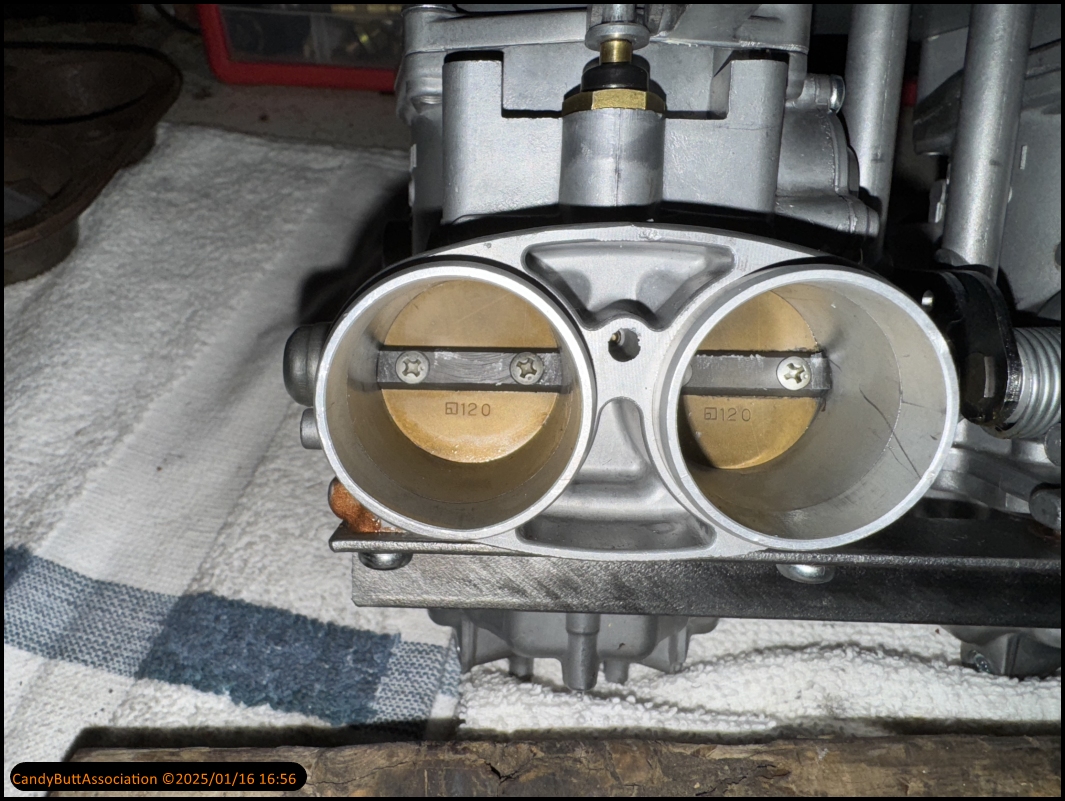

Time to replace the original diaphragms. Note to crinkles and lack of flexibility.

Kawboy taught me a 3 F's.. Form. Fit. Function. So far, so good.

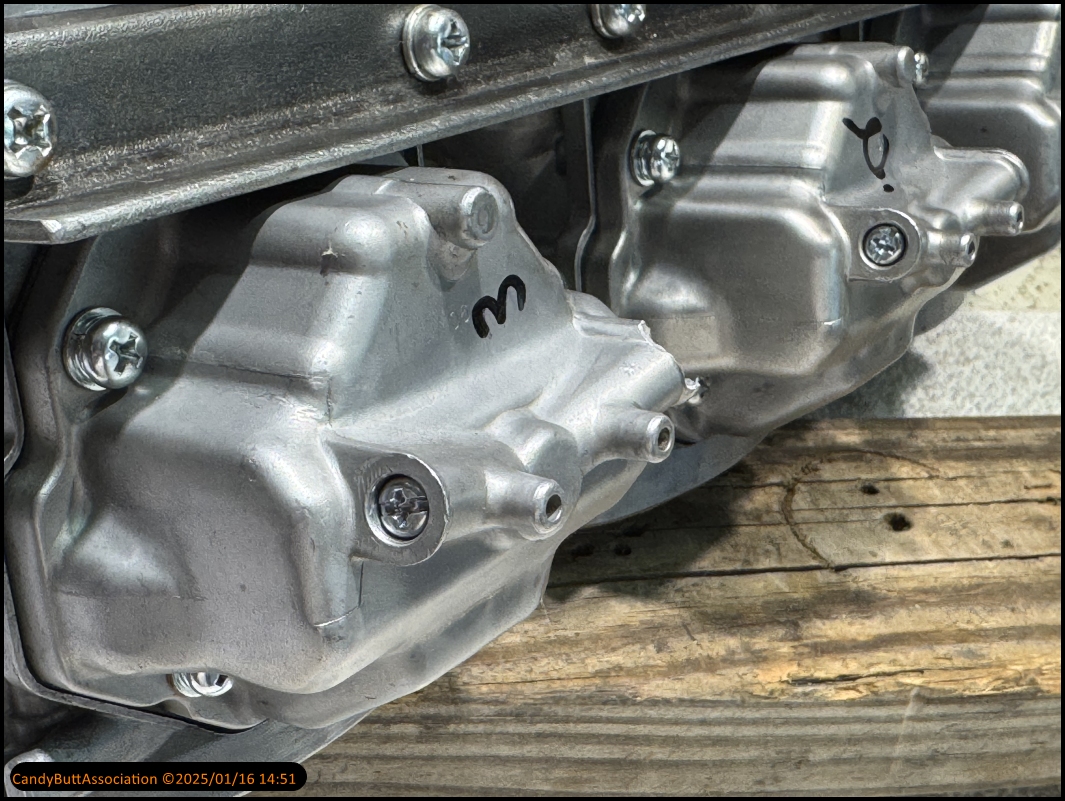

I put witness marks on all the pieces to ensure they went together the same way they came apart.

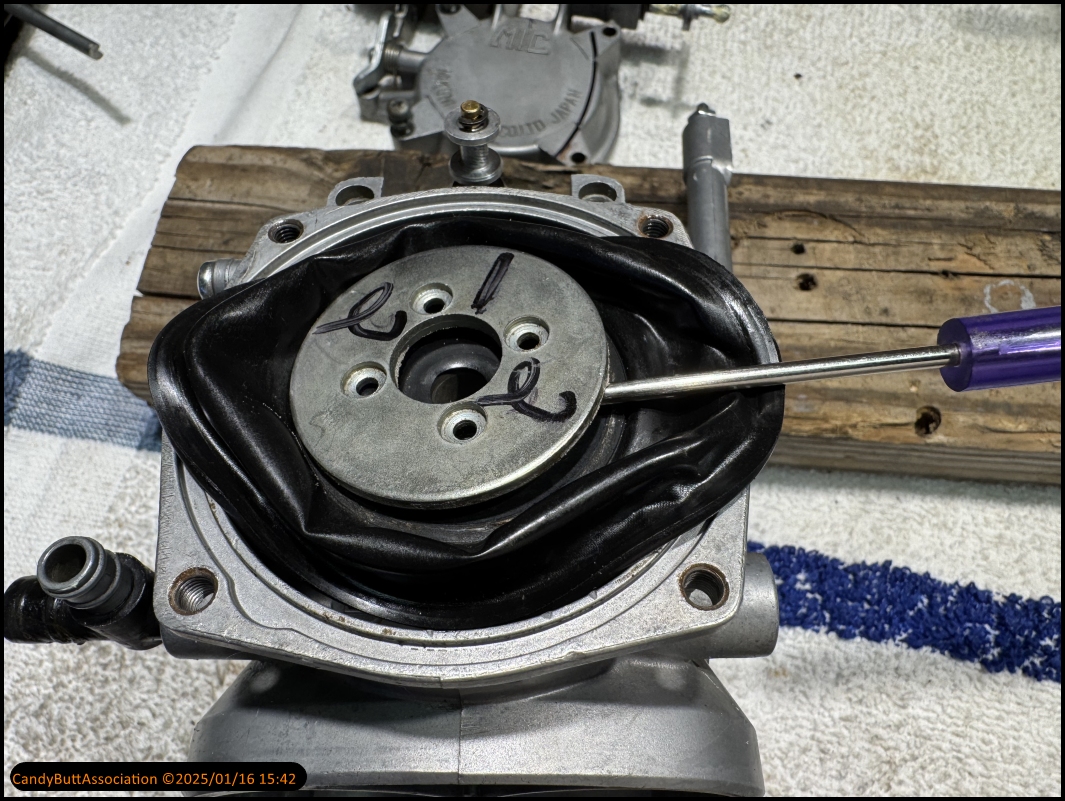

Trying to remove the middle top piece proved to be difficult. What never knows how much forced to use when one has not done the job before..

It turns out after 46 years, the rubber membrane and the metal kind of weld to each other.

I spent well over 15 minutes looking at this very carefully trying just a little bit more force every time.

I started off with a small screwdriver, trying to pop the middle piece off.

Finally, I got it removed without damaging the OEM diaphragm.

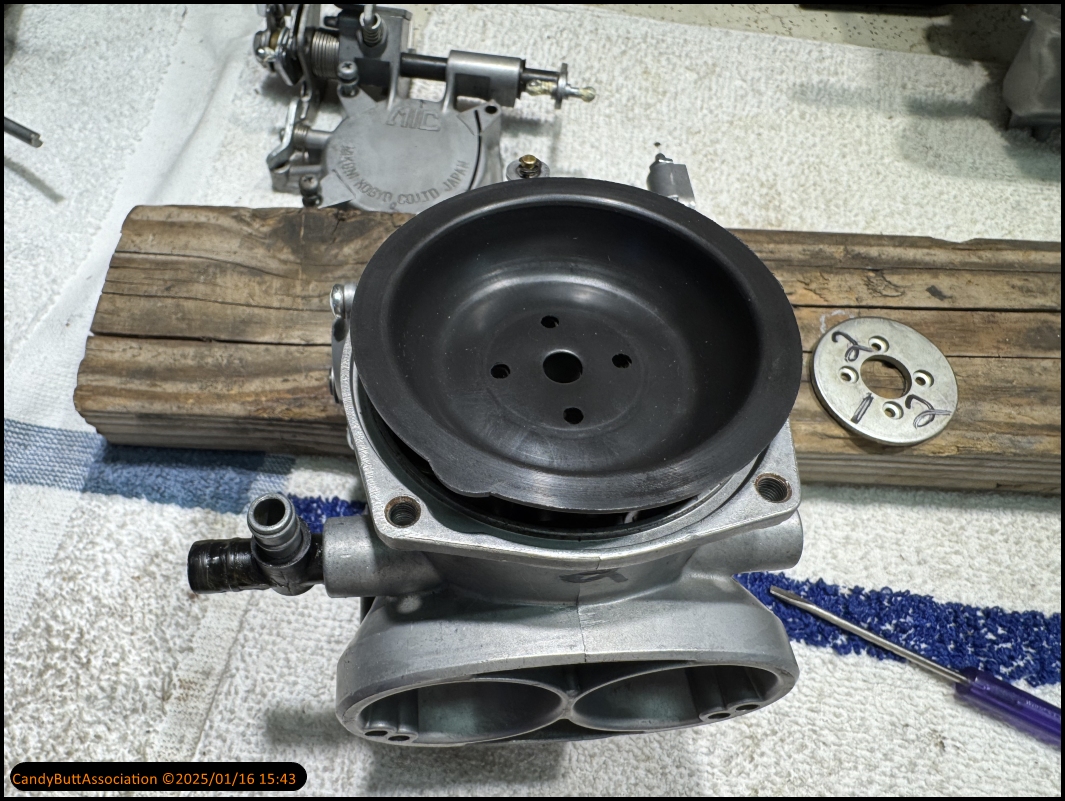

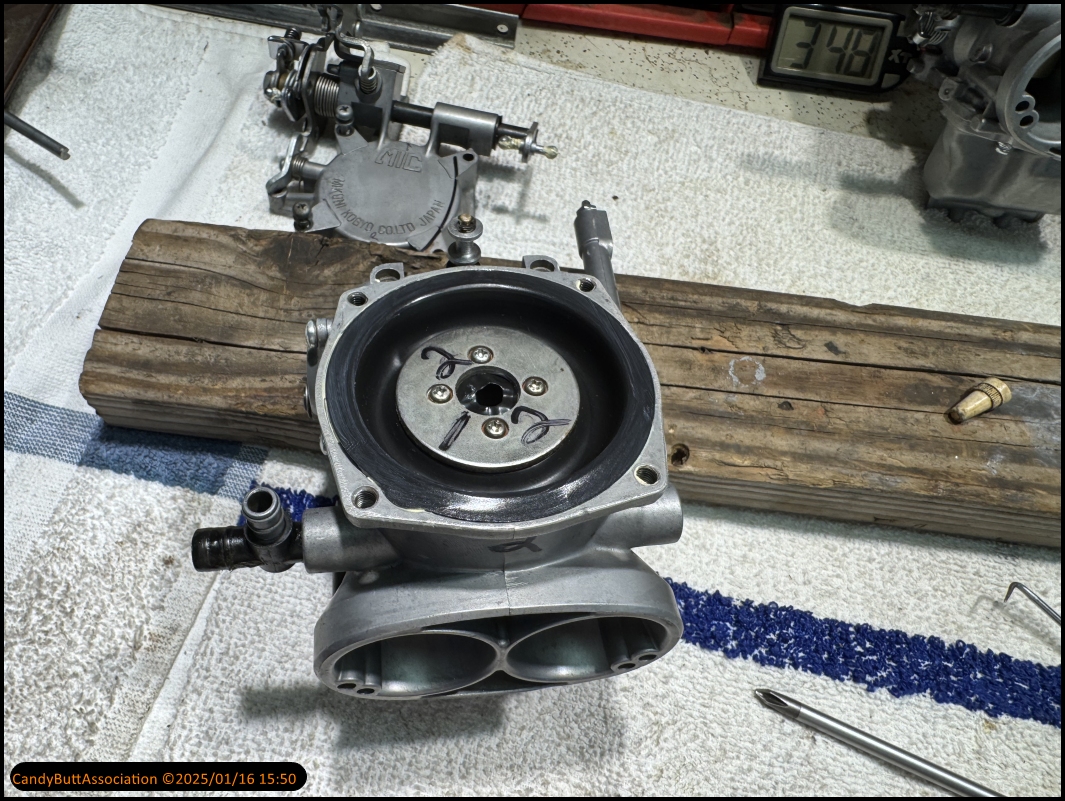

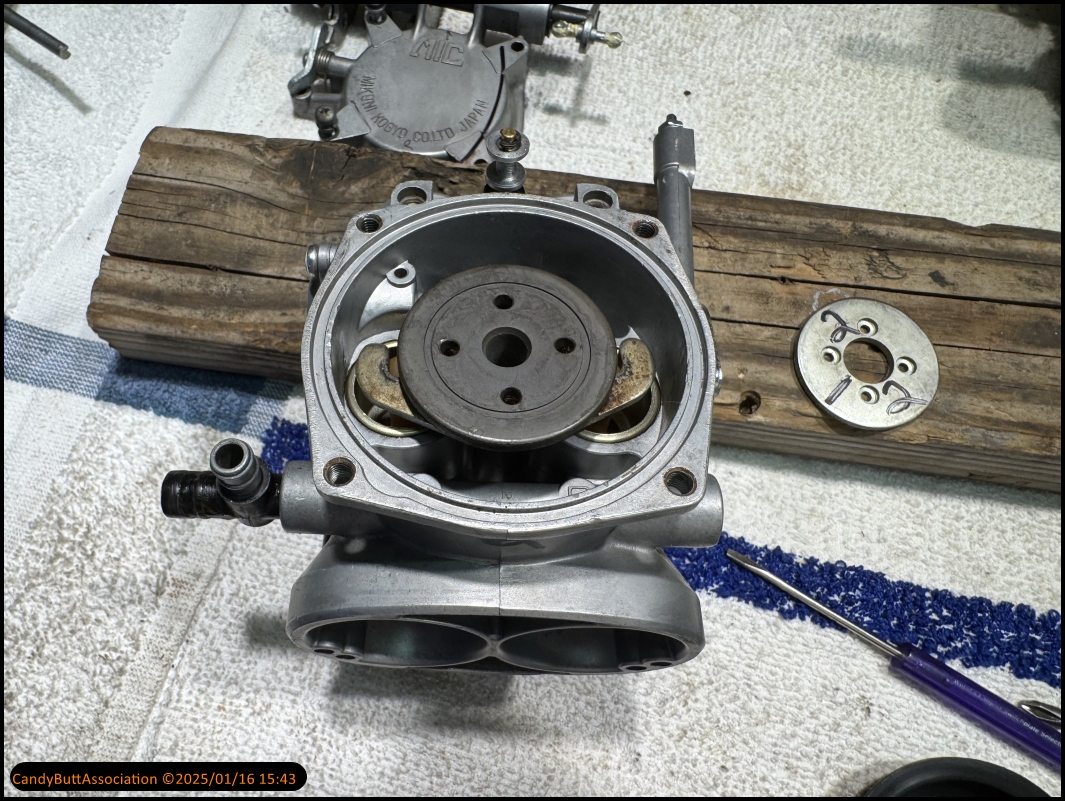

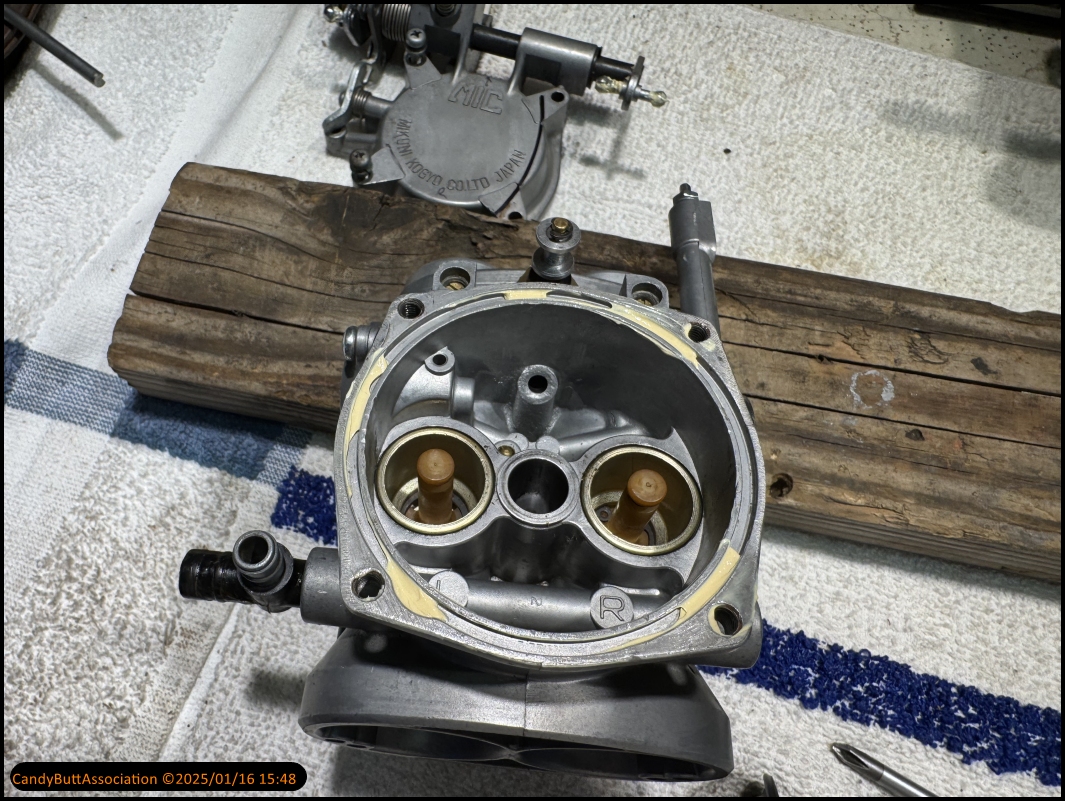

Here's the new one installed. I used a light grease to keep the diaphragm in the groove to ensure a good top piece seal.

Had to chase this thread. The repair turned out good.

For carburetor number two decided to leave the diaphragm and slides installed. I was very careful not to dinging the carburetor body.

This technique worked very well.

Grease in the groove to keep the diaphragm sealed when installing the top hat.

These are the little screws that hold the diaphragm to the slides. Mine came out a little bit rusty.

So I cleaned them up and applied a damn grease before installation.

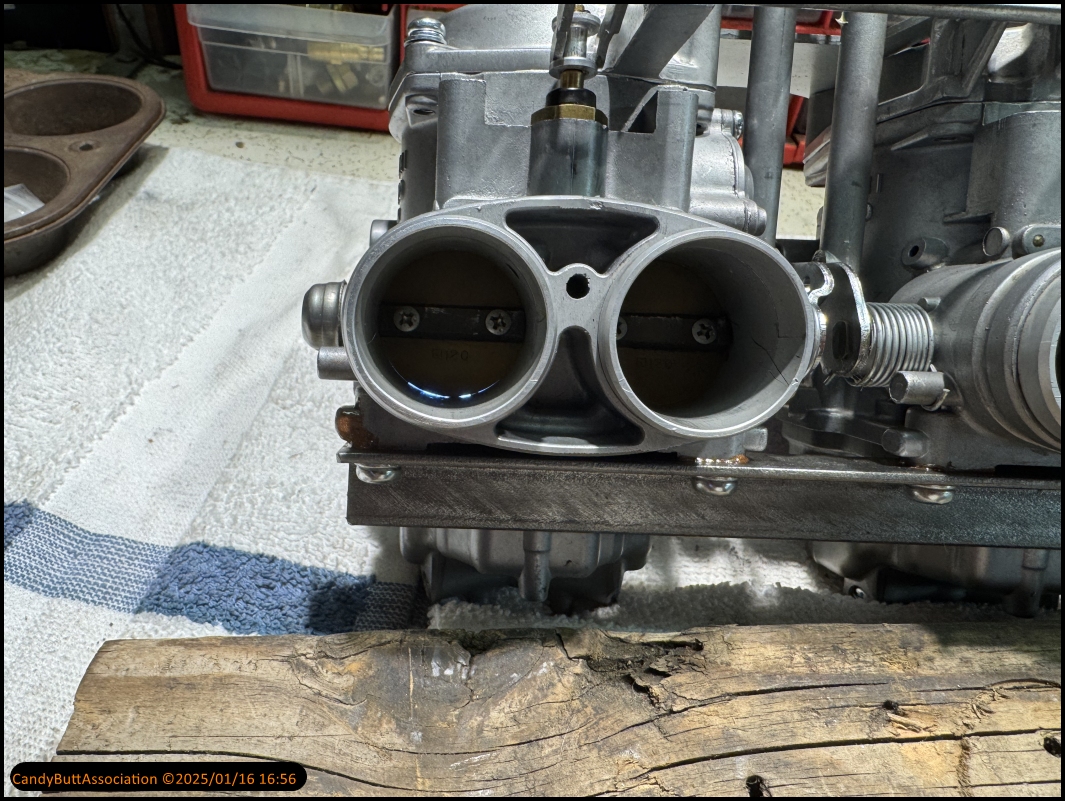

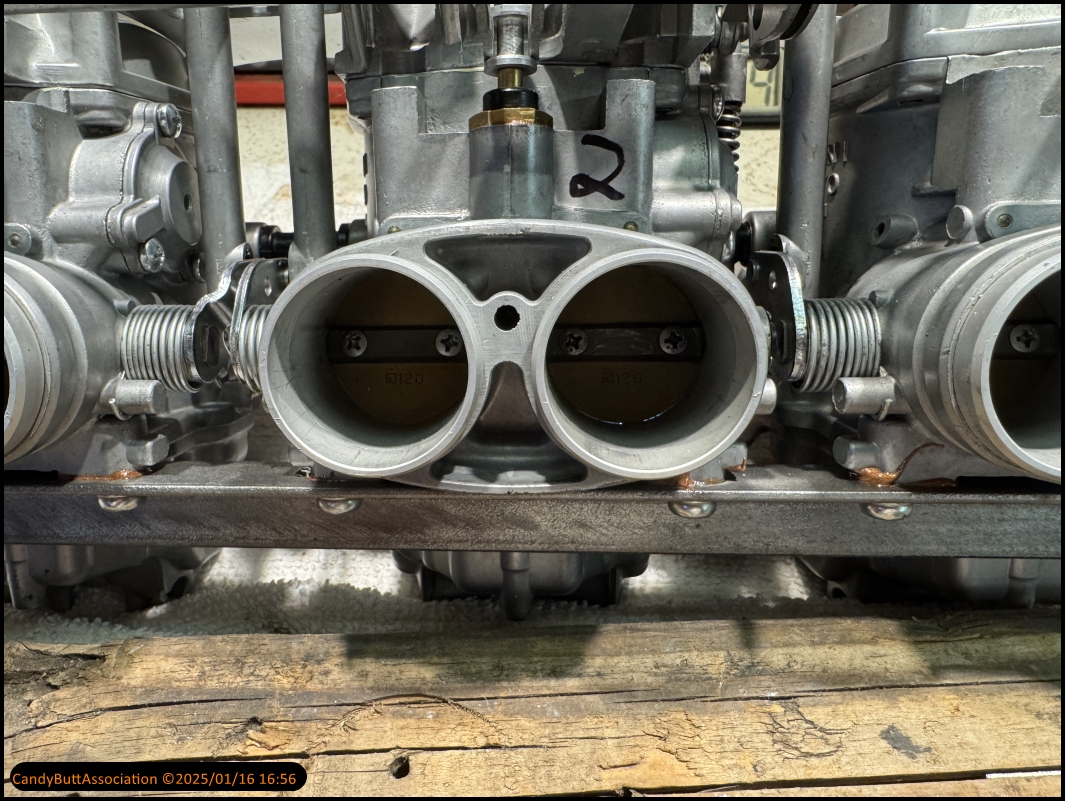

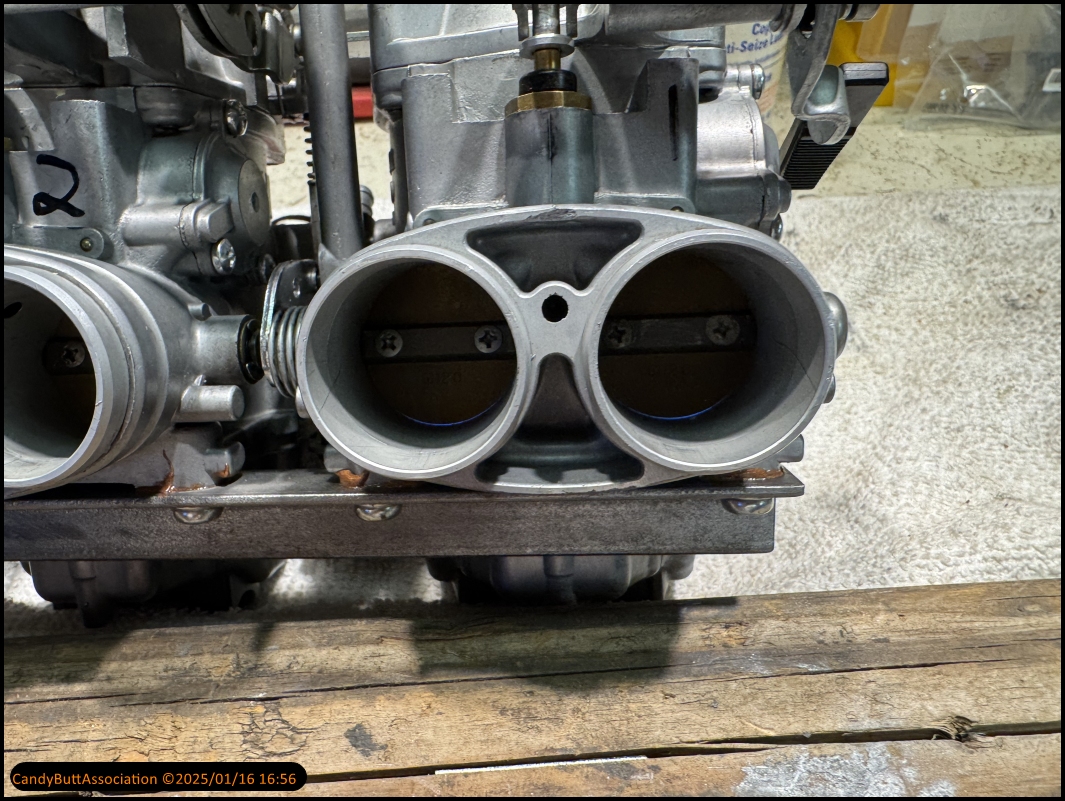

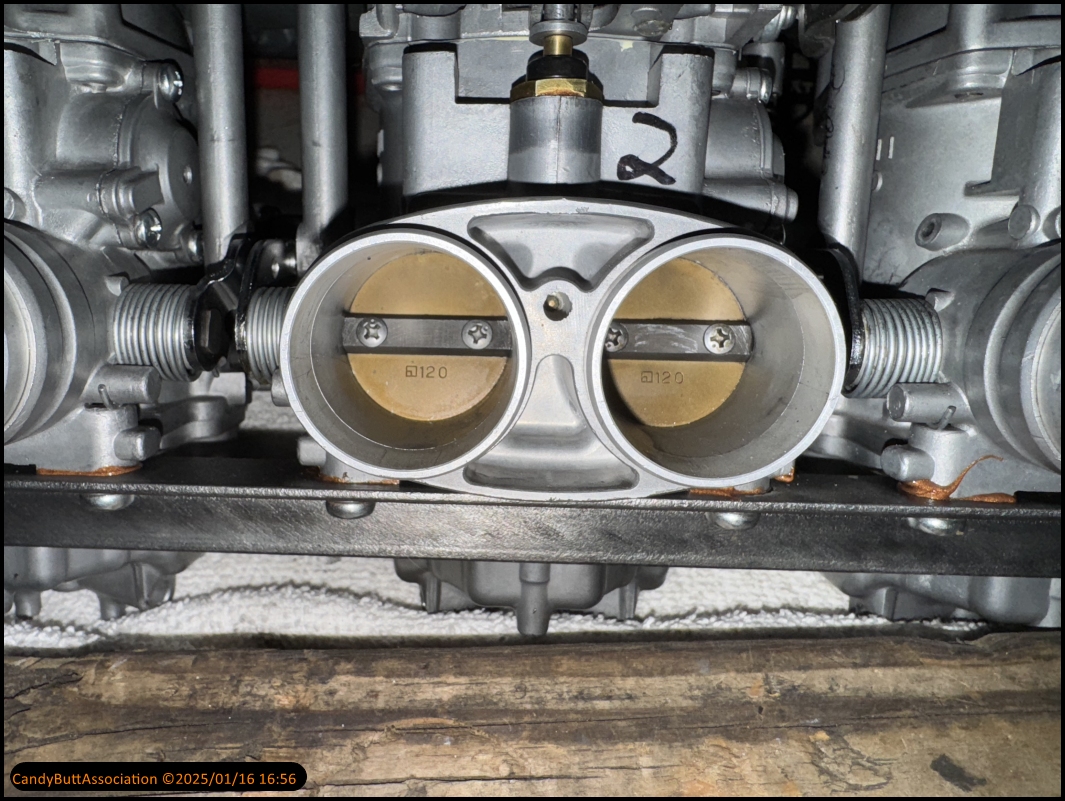

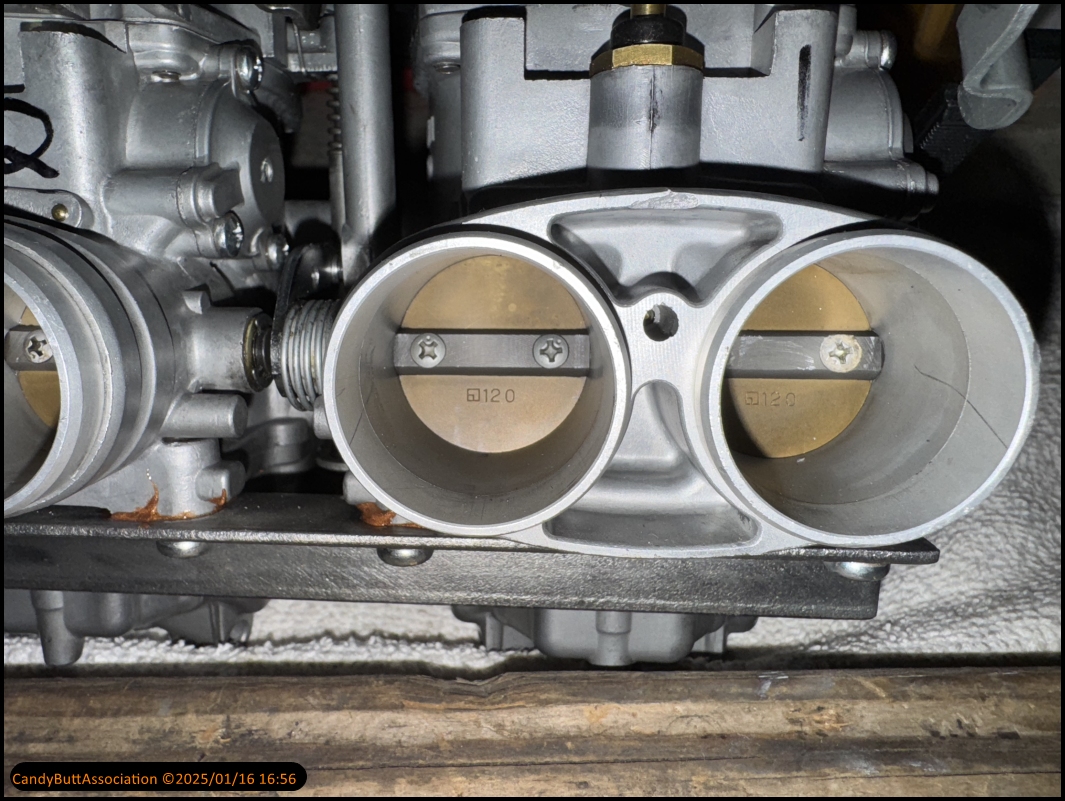

Reassembled the carburetors to make a rack. Then performed a bench sync using flashlights.

Setting the butterflies based upon the amount of light worked very well.

I need to get more flashlights, though I would like to have one for each bore.

When I reassembled the discreet carburetors into a rack, I first snugged the reinforcement bar at the bottom,

Before snugging down the top reinforcement pieces.

They seem to work really well, as the pitch synchronization was super easy, and all six butterflies respond very smoothly.

Before starting the synchronization insured that the actual screw was completely loose as well as the choke circuit cam.

Using these techniques had much better results than the first time I did a bench sync.

As you can see, I used anti seize on support bracket screws. I need to clean this up.

These little flashlights fit perfectly into the carburetor throat,

making synchronization based upon emitted light very easy.

Theme by Danetsoft and Danang Probo Sayekti inspired by Maksimer