- Home

- Forums

- Ride Reports

- MotoBikes

- Restorations

- Wrenching

- 1963 BMW R69s

- 1969 BMW R60/2

- 1978 Yamaha 125

- 1979 KZ1300

- 1979 Kz1300 - Bob's Beauty

- 1981 CBX SuperSport

- 1981 Kz1300 Model A3 - Chocolatie

- 1984 Ford F250 XL

- 1987 ATK

- 1987 MowieMowie

- 1987 RotoTiller

- 1988 Honda Accord Lxi

- 1990 BMW RT100 - Barrie

- 1991 Harley Davidson FLHTCU

- 1992 Johnnie Deere

- 2000 YZ426

- 2002 Dodge Ram

- 2006 Carson RacerX Trailer

- 2006 Host Camper

- 2006 KrZy8

- 2007 Wabs

- 2012 KTM 690R

- 2013 Naomi - FJR 1300

- 2014-08-01 Air Compressor - Sears

- 2017 Kioti

- 2018 Toy Hauler

- 2020 Honda Fit

- 2021 Miscellaneous

- 2024 Log Splitter

- 2024 NeoDyne MC Lift

- 2050 test

- Lil Trlr

- Eats

- RIP

- PC Not

- Cages

- Test

- FJRF Best

- For Sale

Candy Butt Association

World's Wimpiest Riders

You are here

2013-07-30 Unauthorized Throttle Body Sync

Forums:

Stolen from FredW at FJRForum.com

The Really, Definitely, Completely Un-Authorized Throttle Body Sync (TBS)

Re-edited 10/2012

This version of the UnAuthorized TBS procedure is based on a premise; that the ideal throttle synchronization is when the throttle plates are aligned with each other and parallel. After a large number of uses on all generations of FJR1300, this procedure has been found to be very effective. Nobody who has used this procedure has ever said that it made their bike run worse. Most people say that their bike ran smoother (less vibration at ~4k-5k rpm ranges.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

I decided to document this procedure. Not because it is so much different than any of the other UA TBS procedures, but because there are so many Throttle Body Sync discussions online. I'm hoping that this procedure becomes the new, standard non-standard. The concept for this TBS procedure came from a thread / discussion I had with a short duration with an FJRforum member from Maine (Alekso) last year. The idea was to come up with a procedure that wasn't so convoluted and difficult to follow or understand as the original Un-Authorized sync procedure.

For those just tuning in, what's going on here is that the "official" Yamaha throttle body sync procedure, the one called out in the Factory Service Manual (FSM) and specified as a "required" procedure at 4k mi. intervals, is simply an adjustment of the air bypass screws at idle speed. These bypass screws have their primary effect on the cylinder vacuum at idle speed, and have very little to do with how smoothly the engine runs at anything other than at idle or just above. As the throttle butterfly plates open, the tiny amount of air contributed to the total intake by the bypass circuit becomes increasingly less significant, so that by the time you are at 3-4k rpm these screws are pretty much insignificant. What is significant at larger throttle openings would be the relative angles of the throttle plates to each other.

The problem is that the FSM doesn't specify a procedure for properly aligning the throttle plates. They just say that the plates are set at the factory and to leave ‘em the hell alone... ![]() Being gearhead dweebs, we know that to achieve the smoothest possible running engine it is our goal for each of the 4 cylinders to contribute an identical amount of power per stroke. With Electronic Fuel Injection and Electronic Ignitions, the likelihood of balanced fuel delivery and perfect ignition timing is much better than in the bad old days of carburetors and ignition points in the past. So our best tuning opportunity is to try to balance the air intakes, which can be best measured y their intake vacuums.

Being gearhead dweebs, we know that to achieve the smoothest possible running engine it is our goal for each of the 4 cylinders to contribute an identical amount of power per stroke. With Electronic Fuel Injection and Electronic Ignitions, the likelihood of balanced fuel delivery and perfect ignition timing is much better than in the bad old days of carburetors and ignition points in the past. So our best tuning opportunity is to try to balance the air intakes, which can be best measured y their intake vacuums.

Prior "Unauthorised" TBS procedures suggested that you just open the throttle while observing the vacuum gauges and make the mechanical adjustments to the throttle linkage quickly. Surely that may work, but at what rpm do we need to go before the air from those bypass screws is nullified? And how sadistic is it to continually rev your engine while making these fine adjustments? (hint – these adjustments aren't always that quick)

Enter the RDC (Really Definitely Completely) Un-Authorized TBS.

The concept here is pretty simple. To align the throttle plates with each other we just eliminate the air contribution from the air by-pass screws by closing them all the way down before starting. Yep... it's just that simple.

So, to prove the concept I documented my most recent RDC UA TBS using a new (to me) Gunson Carb-tune vacuum gauge that I picked up over the winter:

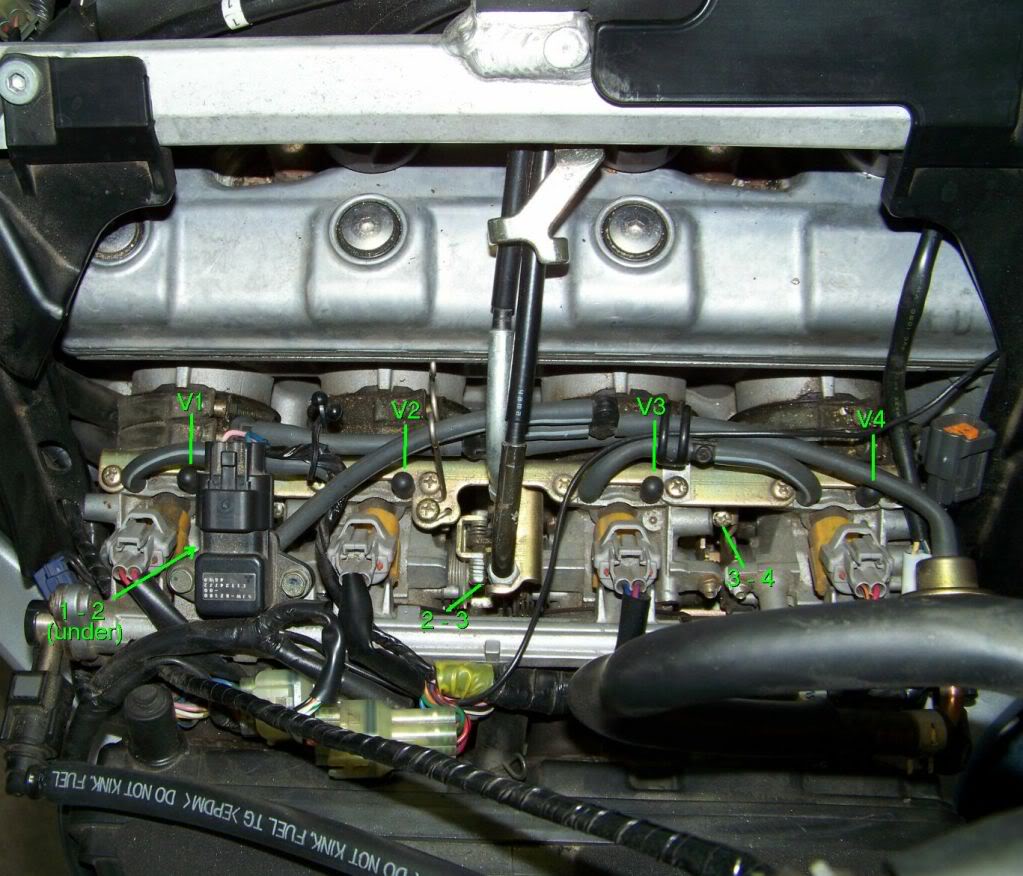

After propping the tank up out of the way, here are the important adjustment points

(note - your under tank could look this uncluttered after installing the WynPro PAIR Block-Off plates and removing all the PAIR crap):

V1 thru V4 are the 4 standard vacuum take-off points for hooking your vacuum gauge of choice to.

1-2, 2-3, and 3-4 are the mechanical linkage adjustment screws to adjust the relative angles of each cylinder's throttle butterfly plate.

Before I began, I documented what I had for vacuum at idle:

Not bad. Notice that #1 is a bit low and #4 is a bit high. Now, without making any adjustment I then revved the engine to ~3-4k rpm and used my Vista Cruise to hold it long enough to snap a picture:

Hello! What's that? Now cyl #1 is high and #4 is low!! This is not good. No, not good at all...

(well, actually these aren't all that bad, but you get the idea...)

Procedure:

Close down (lightly) all 4 of the Air Bypass screws:

Depending on how open they were before, your engine may not want to idle. I would recommend that rather than messing with the idle speed adjust screws that you can use a throttle lock of some type to hold the speed at a reasonable idle. A large ty-wrap around the throttle grip and brake lever will work as a temporary throttle lock for the adjustment. Note: This technique is important for 2nd gen or later FJRs that use an air bypass adjustment for idle speed.

Now that the air screws are closed and out of the picture, you can adjust the throttle plate linkage screws (at idle, not while revving the engine) and balance the vacuums with the throttle plates.

Tip: Start by balancing cyls 2-3 since 1 and 4 are affected by that adjustment. The tricky part is if 2-3 needs adjustment you can't get a screwdriver on the adjustment screw. So, take a guess, shut the engine off, and open the throttle enough to get at the screw head with the engine off. Adjust it one way and then restart the bike to see if you guessed right.

Once 2-3 is good, the 1-2 and 3-4 adjustments can easily be made real-time with the engine running. If you want to rev the engine to various RPMs to see how much things vary (or don't), knock yourself out.

When you are completely happy with the balance, I suggest shutting the engine down, removing your throttle lock device, and then dialing in ~ 1 turn CCW (open) into all 4 of the air bypass screw. Restart the engine and check your idle speed is ~1100rpm. If the idle is too low open each of the 4 air bypass screws the same small amount. Conversely, if the idle is too high, just close them all down an equal amount.

Once you have a good idle speed, recheck your vacuum gauge for balance. Since the throttle plates have already been aligned, if there is any mis-balance, simply adjust the individual air bypass screws until it is balanced again at idle. If the vacuum for a cylinder is too high you’ll want to open the air screw. If the vacuum is too low on one, you will need to close it down to increase the vacuum.

When I had completed this procedure I had dead nutz balance at idle, and it varied very, very little at any throttle opening. The adjustment resulted in a tangible improvement in the amount of vibration. Not where I expected to feel it (idle to 4k rpm) but more so at highway speeds above 4k rpm. Where I used to have a little buzziness above 70 mph there is now an eerie lack of vibration at 75-85 mph. I had previously just considered that buzzing to be the "nature of the beast".

Caveat:

When the throttles valves are nearly closed at idle (1100 rpm) any small amount of crud built up on the faces of those butterflies will have a rather significant impact on the flow, and therefore vacuum, at that minor opening. As you open up all four butterflies (mechanically tied together) that crud will become progressively less significant, and the actual angle of the butterflies will be prevalent.

The premises of the adjustment is that adjusting the tiny crack of an opening at a very low throttle setting (with an assumption of clean or identically dirty throttle plates) will set the throttle plates perfectly parallel to each other, but that wouldn't be true if there was a buildup of spooge on the leading edges of some plates and not others.

What I'd suggest, as a corrective action, would be to clean the throttle bodies and plates with a spray type intake cleaner (I’ve used the spray SeaFoam Creep product) and then recheck your results. I have a good feeling that you'll see that the variability with throttle opening becomes lessened if not eliminated.

Theme by Danetsoft and Danang Probo Sayekti inspired by Maksimer