- Home

- Forums

- Ride Reports

- MotoBikes

- Restorations

- Wrenching

- 1963 BMW R69s

- 1969 BMW R60/2

- 1978 Yamaha 125

- 1979 KZ1300

- 1979 Kz1300 - Bob's Beauty

- 1981 CBX SuperSport

- 1981 Kz1300 Model A3 - Chocolatie

- 1984 Ford F250 XL

- 1987 ATK

- 1987 MowieMowie

- 1987 RotoTiller

- 1988 Honda Accord Lxi

- 1990 BMW RT100 - Barrie

- 1991 Harley Davidson FLHTCU

- 1992 Johnnie Deere

- 2000 YZ426

- 2002 Dodge Ram

- 2006 Carson RacerX Trailer

- 2006 Host Camper

- 2006 KrZy8

- 2007 Wabs

- 2012 KTM 690R

- 2013 Naomi - FJR 1300

- 2014-08-01 Air Compressor - Sears

- 2017 Kioti

- 2018 Toy Hauler

- 2020 Honda Fit

- 2021 Miscellaneous

- 2024 Log Splitter

- 2024 NeoDyne MC Lift

- 2050 test

- Lil Trlr

- Eats

- RIP

- PC Not

- Cages

- Test

- FJRF Best

- For Sale

Candy Butt Association

World's Wimpiest Riders

You are here

2016-09-12 Starter Motor Replacement - 170 Amps!

Forums:

Woke up this morning with every intention of going on a nice ride local La Pine ride. Lots of beautiful area to cover here. First thing I noticed was it's kind of chilly.. about 41F.

Get to KrZy8, all geared up, hit the start button and....

grrrr, grr, gr - cough, run, die.

RuhRohRollie - not good.

Let battery sit for a couple of minutes.

Try again.

On what is obviously the LAST attempt, she fires and keeps the fire - the secret was to give throttle immediately to get off of idle. The volts are so low that the cpu is struggling to provide info. KrZy8 is running CRAP but running! Soon, she's back to normal. I ride around La Pine before stopping for breakfast at the Harvest Depot to get some heat into the engine and charge into the battery.

Clearly, this starter motor will NOT be ignored for this trip. OK during warm/hot weather, no good when chilly. Called Ray, changed my changed plans and headed over after breakfast.

On the lift at approx 10:43. Ray's left arm is kind of messed up after some medical procedure so I did the 'work' while Ray looked on and corrected me from Red Forman dumb-ass maneuvers.

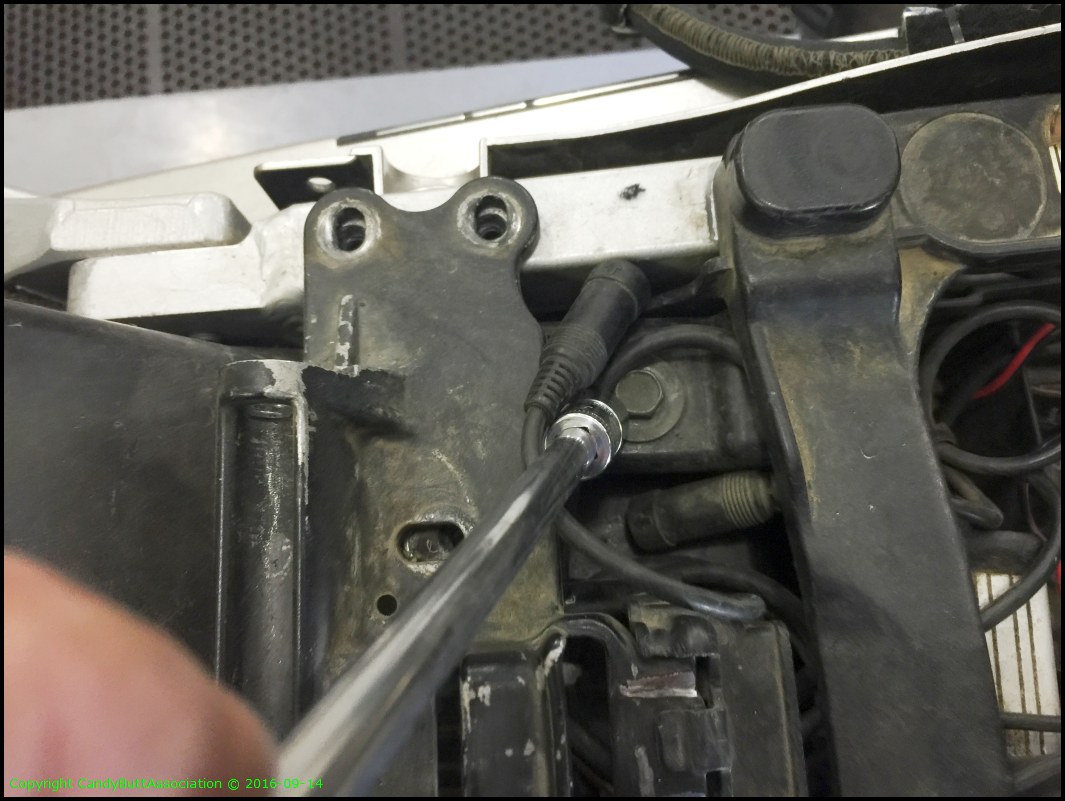

To remove the starter motor, the air box and fuel injector rail have to come out. I have so much extra wiring for farkles. so took these pix to document where everything goes.

Communication loom goes under..

Notice the positioning.. to the hole front side.

Seat height adjustment to the rear position.

Ambient air pressure sensor here and connector.

Time to get the throttle bodies out of here.. They pop off pretty easy with help of leverage. Be gentle.

Throttle body plates are pretty clean. That's good.

Finally, the starter motor comes out. Be careful of the mounting allan bolts. Do NOT mess them up. Clean the holes from debri so the allen key fits in solidly.

Re-installed! We did NOT remove cables or un-needed connectors. Ray used a bungee cord to hold it out of the way while we messed with the starter. We used WD-40 to lube the boots and throats.

We installed the air box twice. We did not like the way #2 seated. Pulling the box, the problem is clear.. This boot is shorter than the others. We lubed them with a light grease and payed special attention to #2. Somewhere in the future I need a new boot or airbox. For now, 1,000 miles from home, it will be just fine, Thank You.

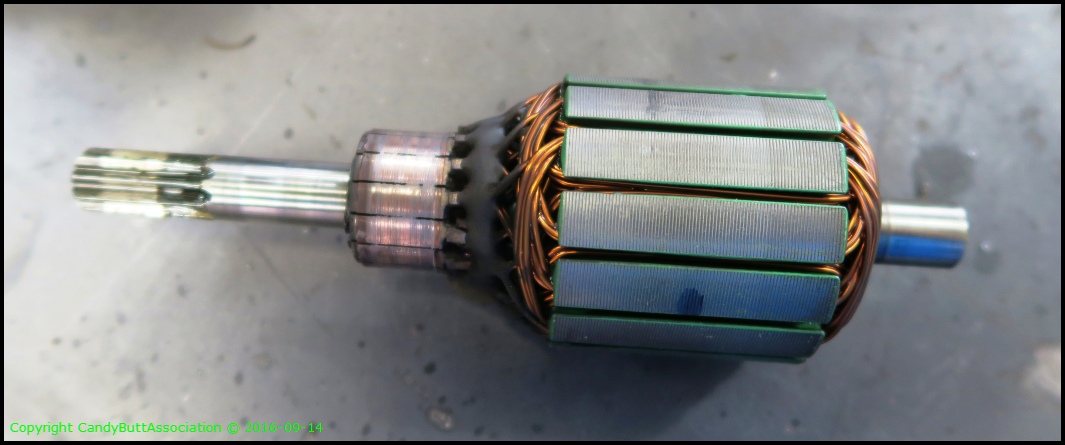

These pix are from the starter motor that came out of KrZy8. Recall this is engine #2, approx 80 to 90k on it now.

The gunk. The oil seal had leaked, and the commutator had bridged segments.

The leaked oil just served a compound to bridge spent carbon from the brushes. Each of the grooves on the copper part to the right of the splined shaft should be clear.. not bridged with conductive gunk.

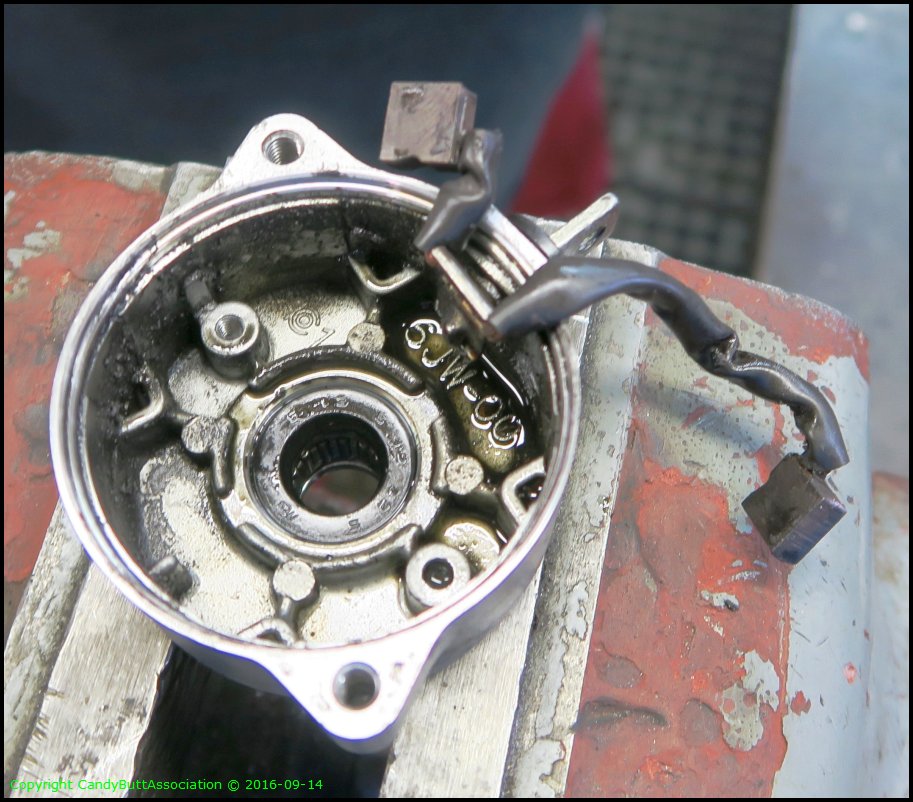

The brush cap.. and signs of oil intrusion.

Ray has an exchange program, 80 bucks plus core. The 'new' e.g. rebuilt starter draws 20 amps on the bench, unloaded. My old one, on the bench, drew a whopping 170 amps! Crap, you can weld with that!

Theme by Danetsoft and Danang Probo Sayekti inspired by Maksimer