- Home

- Forums

- Ride Reports

- MotoBikes

- Restorations

- Wrenching

- 1963 BMW R69s

- 1969 BMW R60/2

- 1978 Yamaha 125

- 1979 KZ1300

- 1979 Kz1300 - Bob's Beauty

- 1981 CBX SuperSport

- 1981 Kz1300 Model A3 - Chocolatie

- 1984 Ford F250 XL

- 1987 ATK

- 1987 MowieMowie

- 1987 RotoTiller

- 1988 Honda Accord Lxi

- 1990 BMW RT100 - Barrie

- 1991 Harley Davidson FLHTCU

- 1992 Johnnie Deere

- 2000 YZ426

- 2002 Dodge Ram

- 2006 Carson RacerX Trailer

- 2006 Host Camper

- 2006 KrZy8

- 2007 Wabs

- 2012 KTM 690R

- 2013 Naomi - FJR 1300

- 2014-08-01 Air Compressor - Sears

- 2017 Kioti

- 2018 Toy Hauler

- 2020 Honda Fit

- 2021 Miscellaneous

- 2024 Log Splitter

- 2024 NeoDyne MC Lift

- 2050 test

- Lil Trlr

- Eats

- RIP

- PC Not

- Cages

- Test

- FJRF Best

- For Sale

Candy Butt Association

World's Wimpiest Riders

You are here

2023-02-03 KZ1300 Valve Check, Cam Chain Adj, Starter Motor Clutch

Forums:

I may have a water leak at front side lhs cylinder.

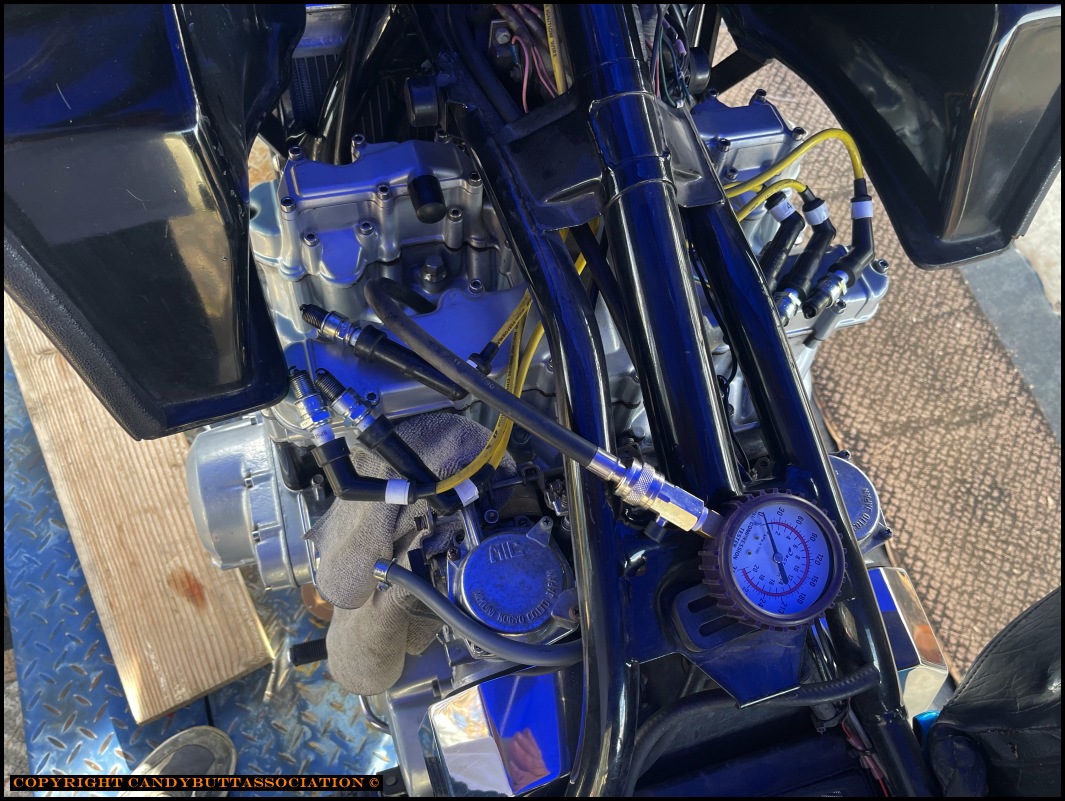

First up, a cold compression test. Yes, I know warm will change numbers and I'll do that later. First things first.

| Cyl | 1 | 2 | 3 | 4 | 5 | 6 |

| Compression | 170 | 150 | 140 | 150 | 155 | 160 |

Spark plugs grounded, just in case...

10 amp battery charger keeps automotive battery fresh for compression test.

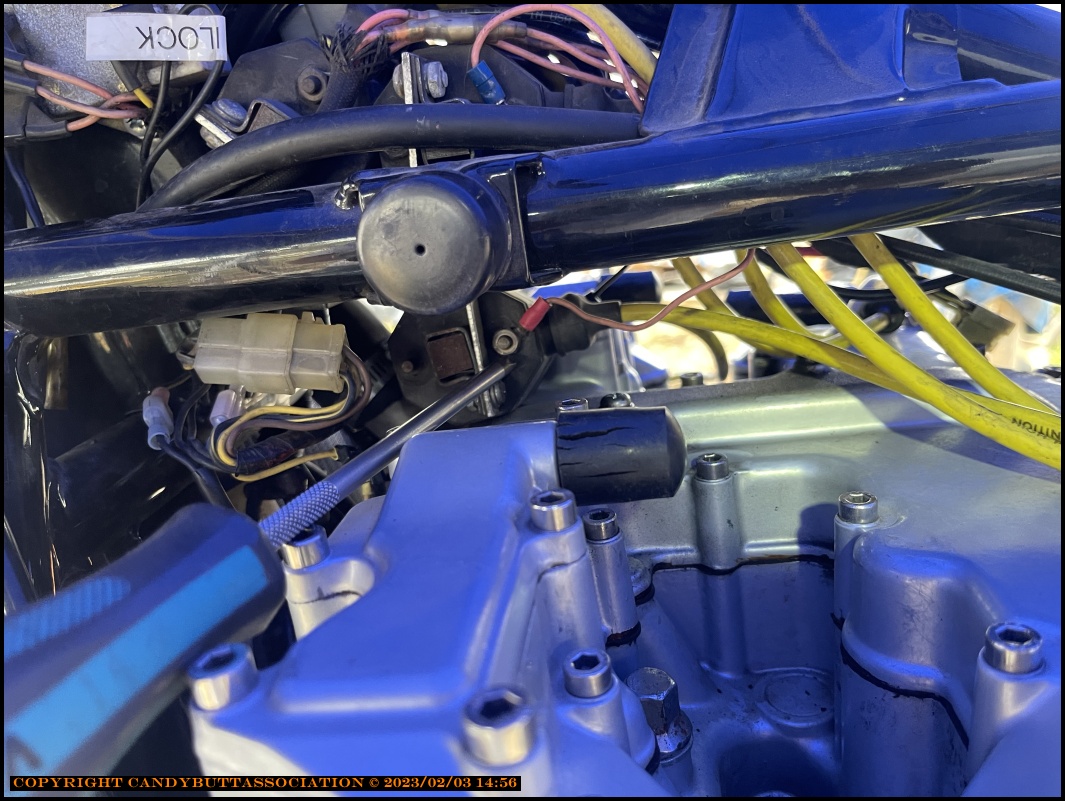

Bottom coil must be removed for valve cover clearance. There's a 5/16 threaded nut up there.. Wish I had

simply tapped the home built bracket I made in 1980...

Phillips headed screw for lower coil is here.

Primary side. Disconnected at connector near coil.

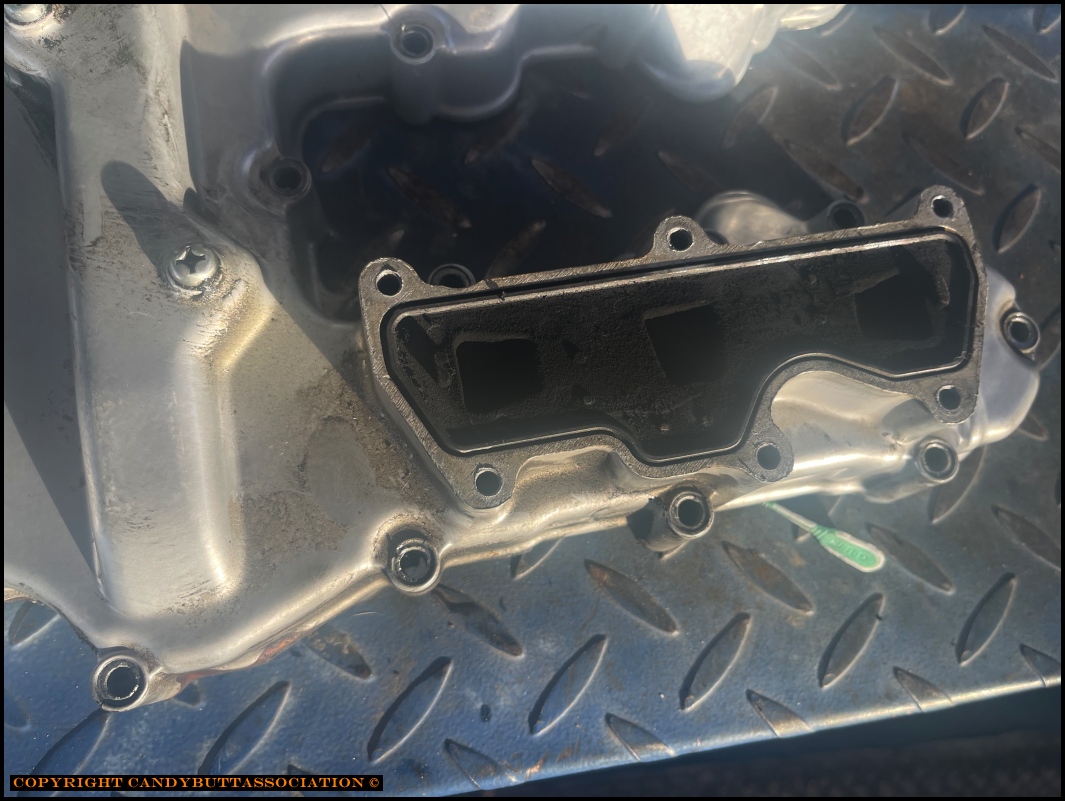

Valve cover removed. Lobes look good.

Topside. Had forgotten I'm still running the reed valves.. but no hoses to pulsate reeds, so really the reeds just provide a 'seal' for reed cover.

Here's a shot of the reed valve cover and bolt template.

Tomorrow or next day will perform valve check.

Theme by Danetsoft and Danang Probo Sayekti inspired by Maksimer

2023-03-02 Cam Chain Tightness Video

Compression Avg and Delta

2023-02-03 Tach Gear - What keeps it captive?

2023-02-04 Tachometer drive gear Answer

When all else fails, RTFM!

CYLINDER HEAD COVER Removal:

eRemove the fuel tank (Pg.46).

eDisconnect the battery ground (-) lead.

eRemove the Allen bolt, stop, and holder, and pull the tachometer pinion holder and pinion with the tachom- eter cable off the cylinder head cover.

2023-02-04 KZ1300 Valve Check cont

edit

2023-02-04 Continuing with Valve Check

Plugs are looking better. I see signs of running rich, but less oil traces than before. This after a 200 mile ride.

Off to checking valve clearances. 'T' mark at case mark, exhaust cam dot at valve head plane.

Cam lobes look shiny and good.

Finally found a good use for old workplace name badge!

Removing old gasket material...

Cleaning up the rubber plug was a true PITA.

I don't trust this one to seal. I have spare new ones.. But right now the wires are soldered. I plan to put a high quality waterproof connector with soldered wire/terminals... later.

Checked the crank for endplay <possible clunking sound?), it is tight.

Found a slight leak at temp sensor.. could this be the 'leak' at LHS cylinder 1 base gasket? Hmmm.

Raw valve data.

What FSM looks like after 44 years of use!

More later...